Exploring Motor Stator Test System

Motor Stator Test System

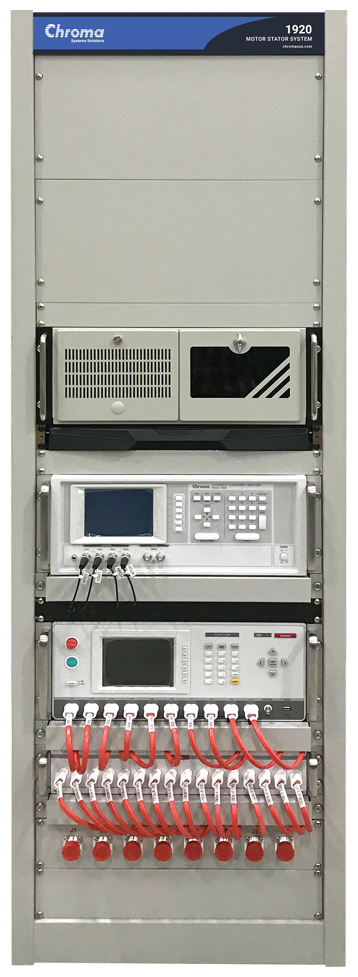

Chroma 1920

For electrical safety and quality testing functions of motor stator coils

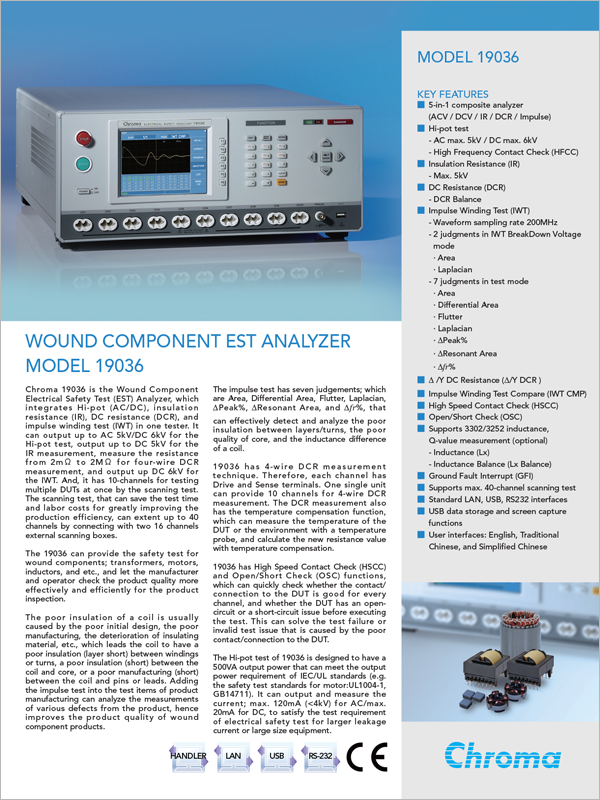

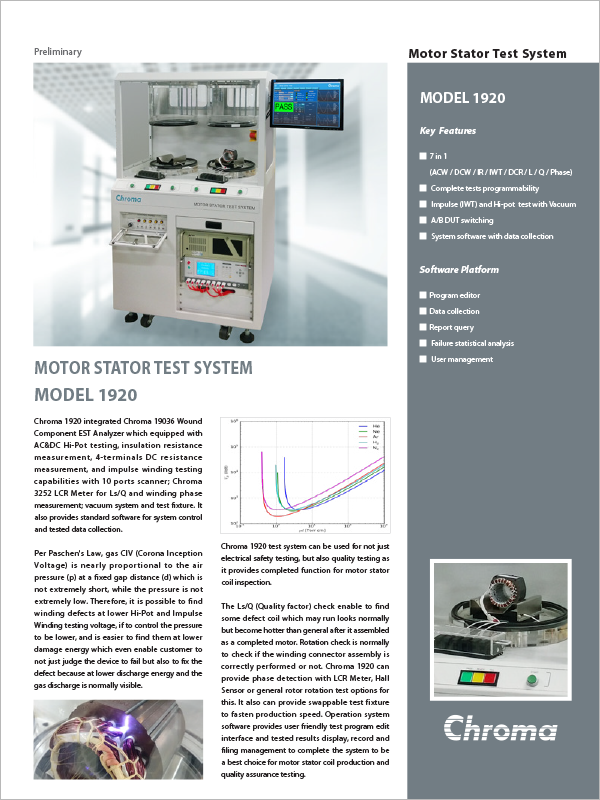

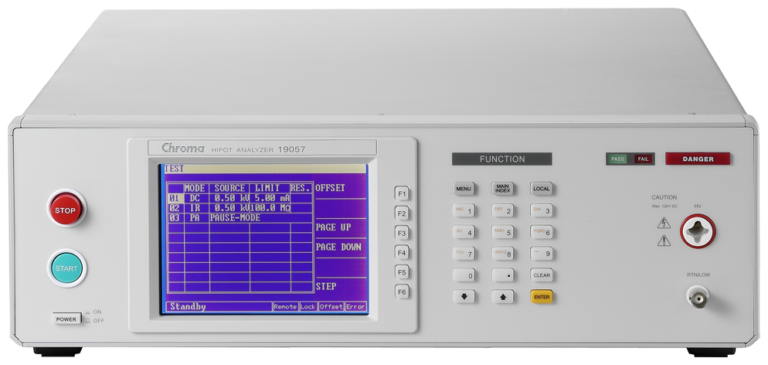

The new Chroma 1920 integrates several of Chroma’s best instruments: the Chroma Wound Component EST Analyzer Model 19036, equipped with AC & DC Hi-Pot testing, insulation resistance measurement, 4-terminal DC resistance measurement, and impulse winding test capabilities with 10 ports for scanning; the Chroma LCR Meter Model 3252 for Ls/Q and winding phase measurement; a vacuum system and a test fixture. It also includes standard software for system control and test data collection.

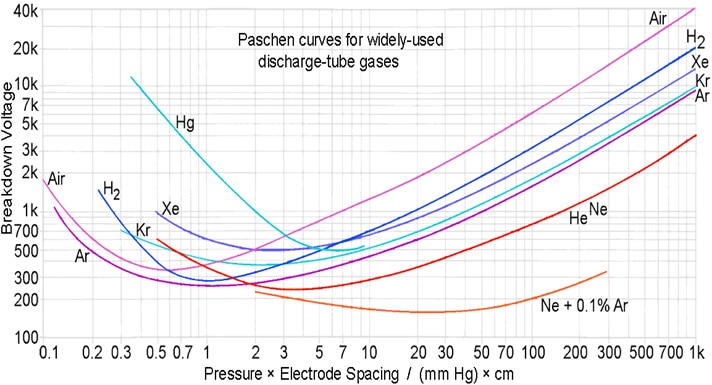

Paschen’s Law

Paschen’s Law is an equation that provides the breakdown voltage, that is the voltage necessary to start a discharge or electric arc, between two electrodes in a gas as a function of pressure and gap length. Per Paschen’s Law, gas CIV (Corona Inception Voltage) is nearly proportional to the air pressure (p) at a fixed gap distance (d). Because of this, it is possible to detect winding defects at lower Hi-Pot and Impulse Winding test voltages under partial vacuum. This also makes it easier to find defects at less damaging energy levels, making it possible to not only judge that the device failed but to also fix the defect, because at lower discharge energy the gas discharge is more visible.

The Chroma 1920 test system can be used not just for electrical safety testing, but also for quality testing, as it provides complete functions for motor stator coil inspection. The Ls/Q (Quality factor) check enables the system to find defective coils which may run and look normal but become hotter than desired after assembled as a complete motor. The Rotation check is normally used to check that the winding connector assembly is correctly performing or not. The Chroma 1920 can also provide phase detection with an LCR Meter, Hall Sensor or general rotor rotation test options designed for this. We can provide swappable test fixtures to improve production speed. The operation software provides a user friendly test program editing interface and test results display, as well as record and file management to complete the system as the best choice for motor stator coil production and quality assurance testing.

Features and Software Platform

- 7 in 1 (ACW / DCW / IR / IWT / DCR / L / Q / Phase)

- Complete tests programmability

- Impulse (IWT) and Hi-pot test with Vacuum

- A/B DUT switching

- System software with data collection

Software Platform

- Program editor

- Data collection

- Report query

- Failure statistical analysis

- User management

Quality Factor Check

The Ls/Q (Quality factor) check enables the system to find defective coils which may run and look normal but become hotter than desired after assembled as a complete motor. The Rotation check is normally used to check that the winding connector assembly is correctly performing or not. The Chroma 1920 can also provide phase detection with an LCR Meter, Hall Sensor or general rotor rotation test options designed for this. We can provide swappable test fixtures to improve production speed. The operation software provides a user friendly test program editing interface and test results display, as well as record and file management to complete the system as the best choice for motor stator coil production and quality assurance testing.

More Features

Lorem Ipsum

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Nam eget velit est. Nulla facilisi.

Lorem Ipsum

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Nam eget velit est. Nulla facilisi.

Lorem Ipsum

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Nam eget velit est. Nulla facilisi.

Lorem Ipsum

Lorem ipsum dolor sit amet, consectetur adipiscing elit. Nam eget velit est. Nulla facilisi.

Watch

Stators, Transformers, Inductors: Solving Issues of Testing for Safety and Quality

This seminar covers some of the standards related to these components, test equipment, and test methods to comply with those safety and quality standards. We also introduce a new solution that performs multiple tests in one instrument; saving resources and increasing throughput. Tests include Impulse winding, hipot and flashover detection, insulation resistance, and DCR measurements.