Exploring Milliohm Meters

Milliohm Meters

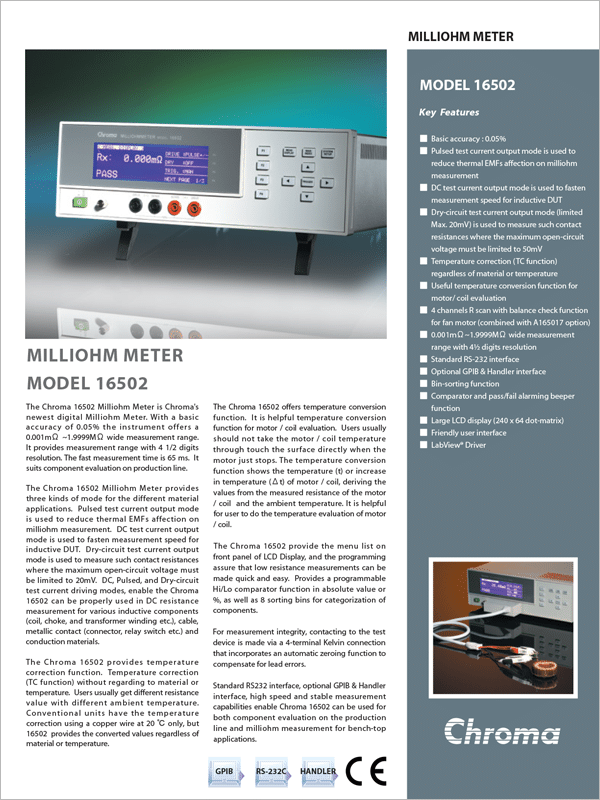

Chroma 16502

Perfect solution for measuring low resistance measurement or conductive characteristics of devices such as switches, relays connectors and printed circuit boards

Test Levels

0.001mΩ~1.9999MΩ

Basic Accuracy

0.05%

Measurement Time

65ms~650ms

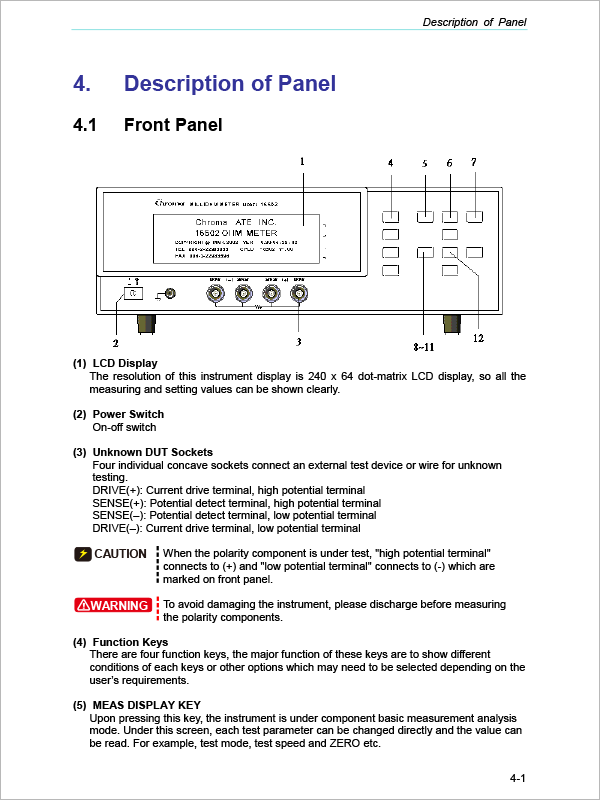

With a basic accuracy of 0.05%, Chroma 16502 offers a 0.001mΩ ~1.9999MΩ wide measurement range. It provides measurement range with 4 1/2 digits resolution. The fast measurement time is 65 ms. It suits component evaluation on production line. Pulsed test current output mode is used to reduce thermal EMFs affection on milliohm measurement. DC test current output mode is used to fasten measurement speed for inductive DUT. Dry-circuit test current output mode is used to measure such contact resistances where the maximum open-circuit voltage must be limited to 20mV.

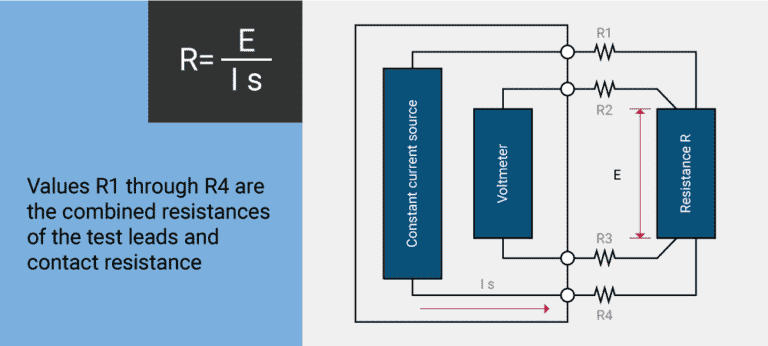

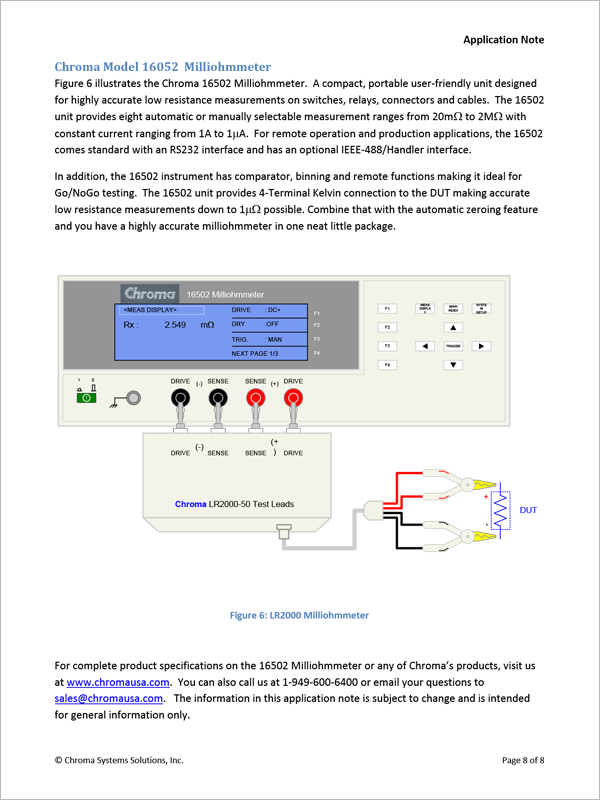

Four-terminal Resistance Measurements

With two-terminal measurements, the conductor resistance of the test leads and the contact resistance of the connections are included in the measured resistance, resulting in measurement errors. The four-terminal measurement method employs a very high input impedance voltmeter, whereby almost all measurement current is conducted through measured resistance R. By measuring the voltage drop across only R, its resistance is measured without being significantly affected by R1 to R4.

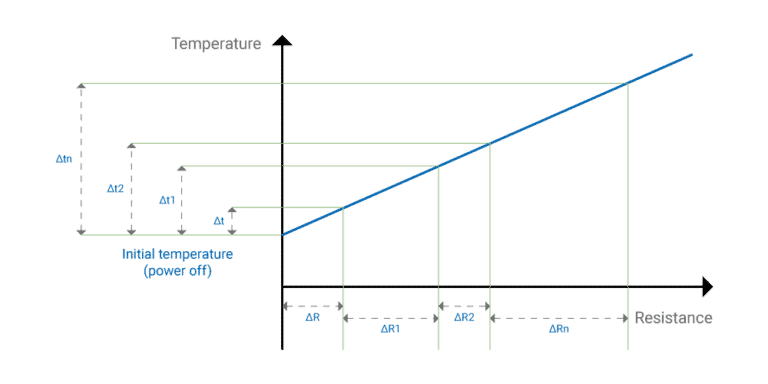

Temperature Compensation

Using the Chroma A165015 temperature probe with temperature function interface card (A165013/A165014), Chroma 16502 is able to correct the displayed resistance value to the required temperature by any thermal coefficient. A lot of material's resistance will be of different value by the different ambient temperature. This function minimizes complex calculation and calculation errors.

Conventional units have temperature correction using a copper wire at 20 ℃, but the 16502 provides converted values regardless of material or temperature. Chroma 16502 supports two common types of temperature probe, PT100 and PT 500. Users just plug the temperature probe in the interface card with temperature function at back panel. Users also can key in the ambient temperature without the temperature probe to get temperature correction.

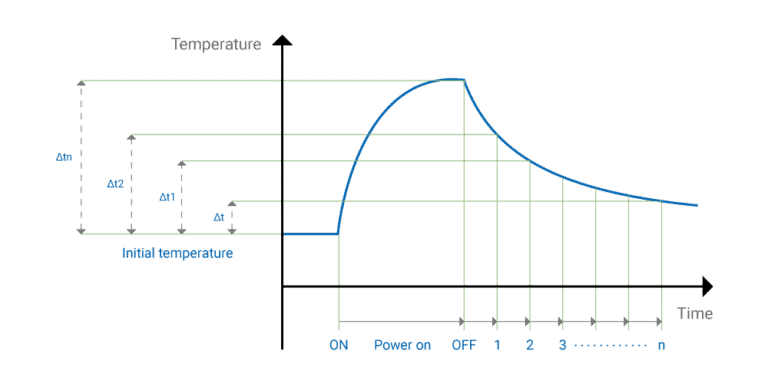

Helpful Temperature Conversion Function for Motor/Coil Evaluation

Using the Chroma A165015 temperature probe with temperature function interface card (A165013/A165014), Chroma 16502 is able to display the temperature (t) or increase in temperature (Δt) of an object, deriving the values from the measured resistance of the object and the ambient temperature. Chroma 16502 supports two common types of temperature probe, PT100 and PT500. Users just plug the temperature probe in the interface card with temperature function at back panel.

This function is especially useful for verifying motor windings or coils, where the maximum temperature increase needs to be determined when current is applied. It is also possible to use the calculated value for making comparisons. When evaluating motors and coils, it is necessary to confirm the maximum temperature increase that will occur while power is applied to the component. This function makes it easy to estimate the maximum temperature. The temperature conversion function can not be used at the same time as the temperature compensation function.

More Features

Temperature Correction

(TC Function)

Comparator and PASS/FAIL Alarming

Beeper Function

Wide

Measurement Range

User-Friendly

Interface

Watch

Webinar: Electrical Safety Testing 101

Get an overview of the basic principles of electrical safety testing.