Exploring Capacitor Leakage Current/IR Meter

Capacitor Leakage Current/IR Meter

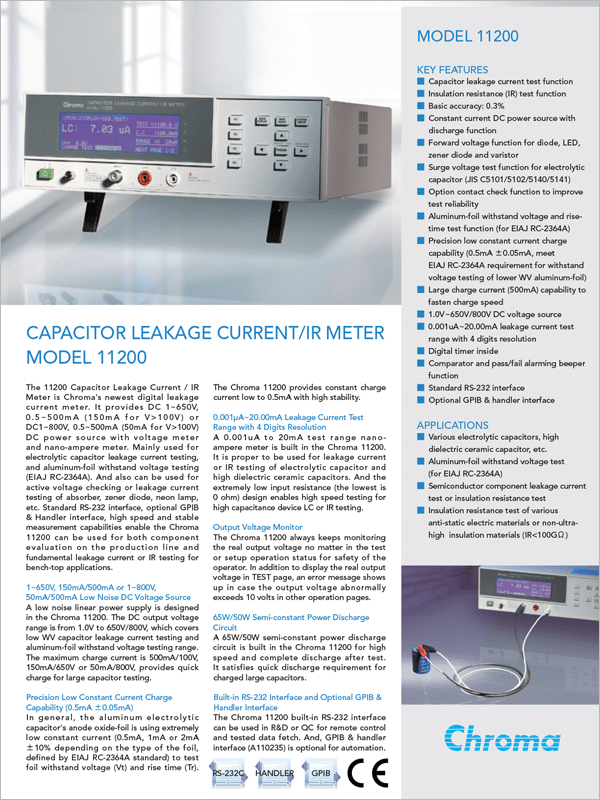

Chroma 11200

Used for both component evaluation on the production line and fundamental leakage current or IR testing for bench-top applications

Test Levels

1.0~100V, step 0.1V: 101~650V

or 800V, step 1V

Basic Accuracy

0.3%

Measurement Time

77mS~420mS

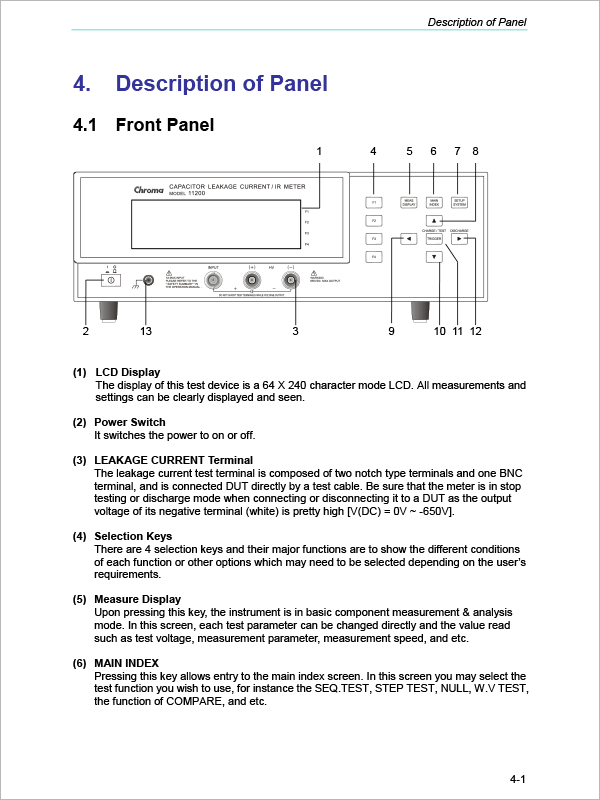

The 11200 Capacitor Leakage Current / IR Meter is mainly used for electrolytic capacitor leakage current testing and aluminum-foil withstand voltage testing (EIAJ RC-2364A). The 11200 can also be used for active voltage checking or leakage current testing of absorber, Zener diode, and Neon lamp etc. With the standard RS232 interface, optional GPIB & Handler interfaces, high speed and stable measurement capabilities, the Chroma 11200 can be used for both component evaluation on the production line and for fundamental leakage current or IR testing for bench top applications.

Standard Leakage Current Testing for Various Electrolytic Capacitors

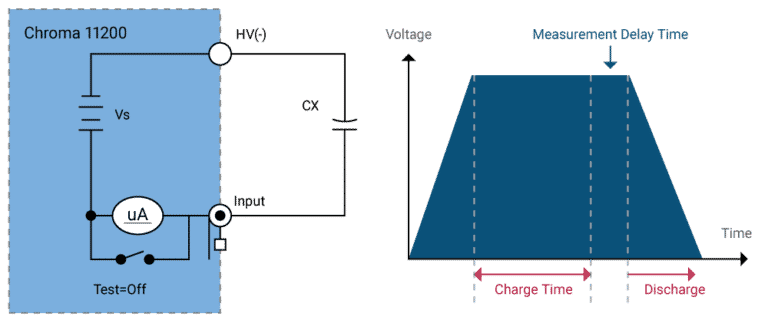

Capacitor leakage current is defined in standards. In general, the leakage current is after charged (the Chroma 11200 is using 98% for identity) plus a period time (for example 60 sec. ±10 sec.). Chroma 11200 provides a semi-constant-power discharge circuit for quick discharge after testing. Therefore, selecting [SEQuence] test mode for this application is recommended. It will follow the preset time to charge, test and then discharge. After that, it will display the tested result and judge pass/fail.

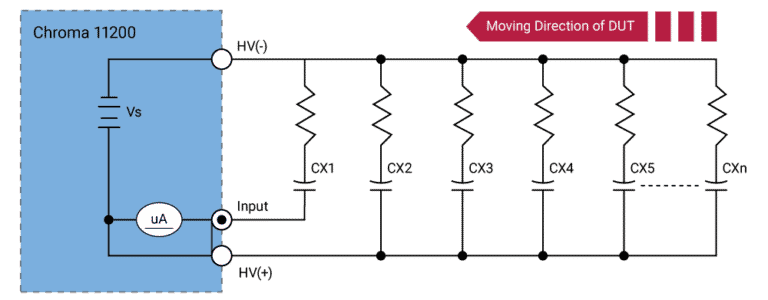

Automatic Production Test for Various Electrolytic Capacitors

On the automatic production line of electrolytic capacitors, generally, several pre-charging station are built with a current limit series resistor in each station. When set the meter in [STEP] test mode, TEST status, measure the leakage current via an external trigger. Chroma 11200 provides up to 500mA (below 100 volts) large output current and low noise voltage source which can be used as charging and testing voltage source. The tested result will be displayed including pass/fail judgment. In addition, it can be controlled through the GPIB interface and handler interface for automation.

More Features

0.001uA – 20.00mA Leakage Current Test Range with 4 Digits Resolution

Comparator and PASS/FAIL Alarming

Beeper Function

Easy Use Gaphic User Interface: Softpanel (Option)

Optional GPIB &

Handler Interface

Chroma 11200 has built-in RS-232 interface which can be used in R&D or QC for remote control and tested data fetch. Additionally, GPIB & handler interface (A110235) are optional for automation.

Model Options

| Model | Description |

| 11200 | Capacitor Leakage Current / IR Meter 650V |

| 11200 | Capacitor Leakage Current / IR Meter 800V |

| 11200 | Capacitor Leakage Current / IR Meter with contact check function 650V |

| Accessories | |

| A110235 | GPIB & Handler Interface |

| A110236 | Rack Mounting Kit |

| A112001 | Triangle Test Fixture for manual test | A112004 | SoftPanel Software |

| 11920 | SoftPanel Kit |

| A112005 | Option 800V |

| A112006 | Contact Check Function for automation test |

Watch

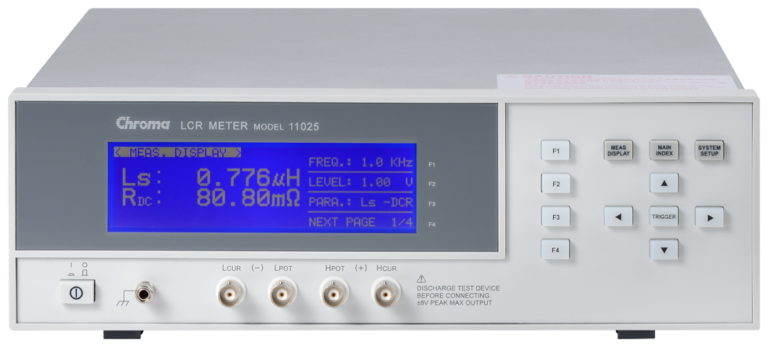

LCR Meters: Selecting Precision Equipment for Low, Mid, and High Frequency Impedance Measurements

This seminar covers Chroma LCR test instruments that not only analyze the characteristics of components but also help to optimize the entire application process including automated manufacturing assessment, incoming and outgoing material inspection, quality verification, and R&D analysis in order to meet low cost, high efficiency requirements.