Webinar: EV Power Components, A Total Testing Solution from the EVSE to the Battery

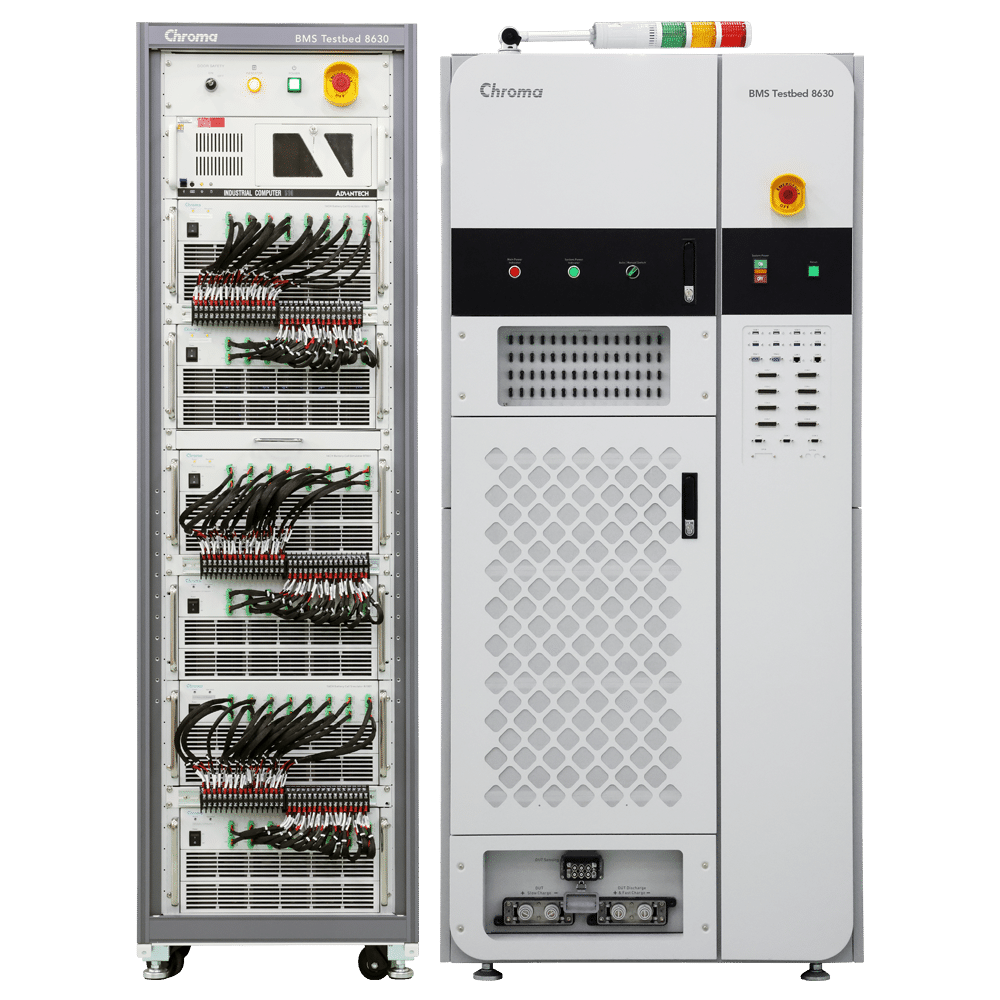

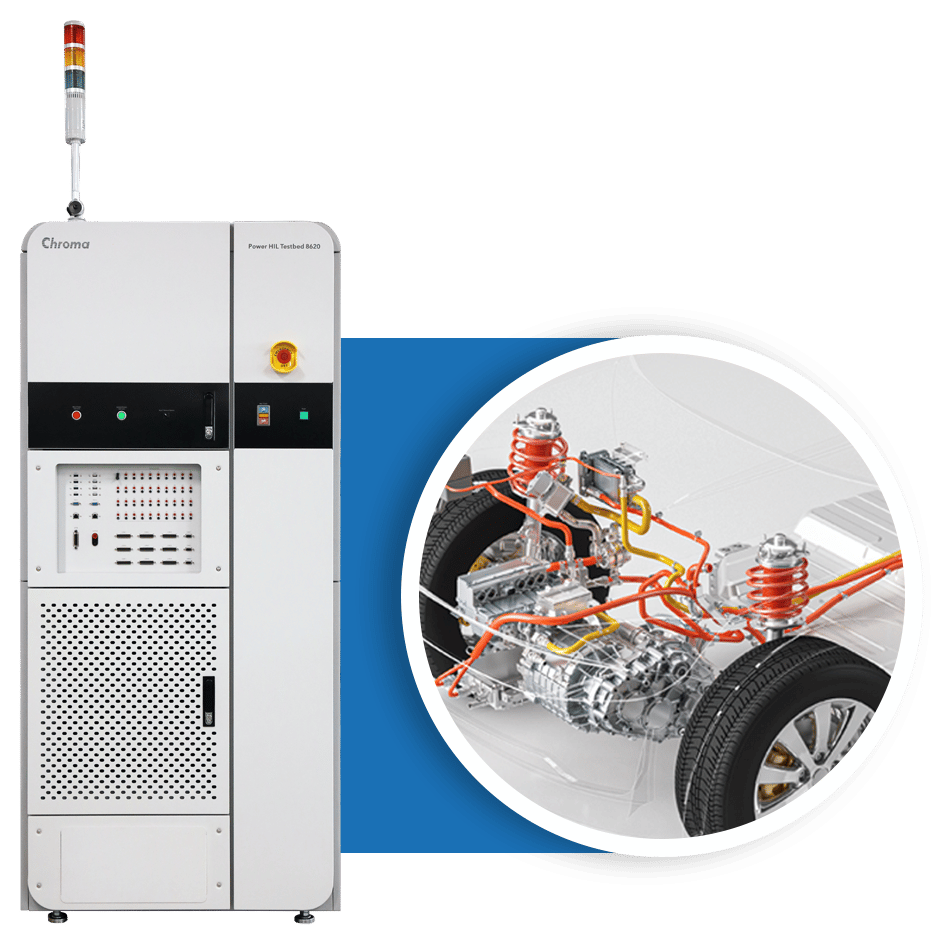

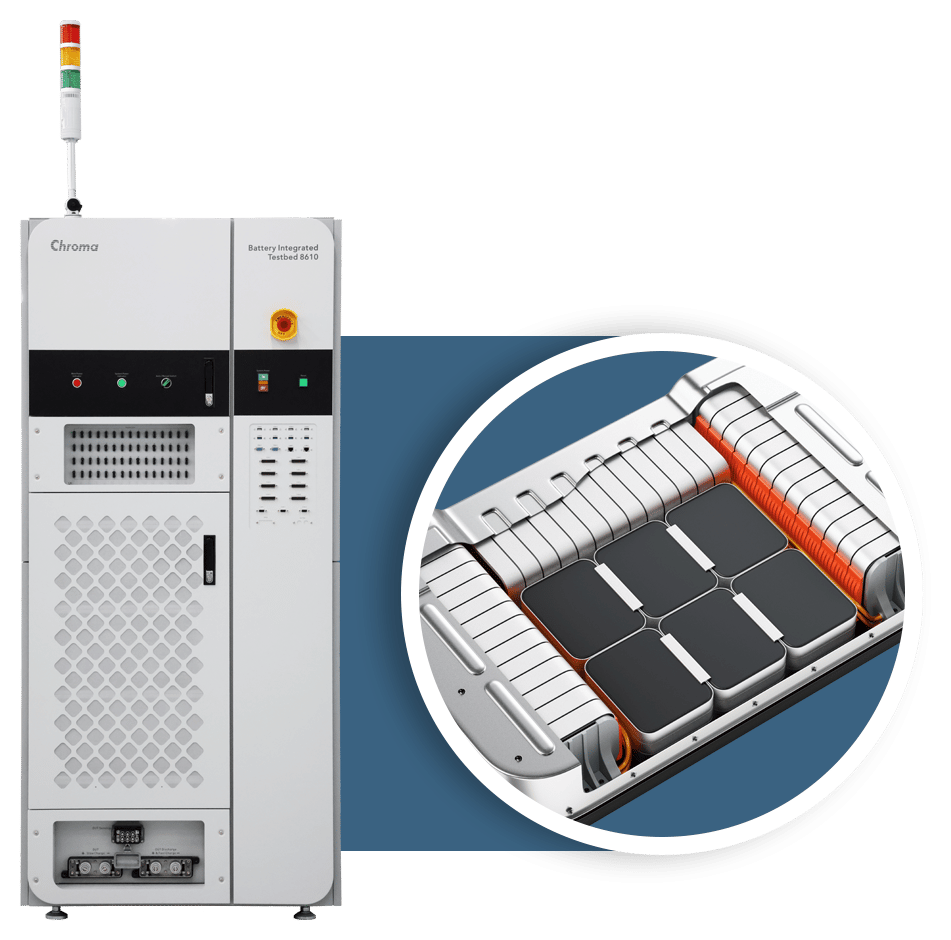

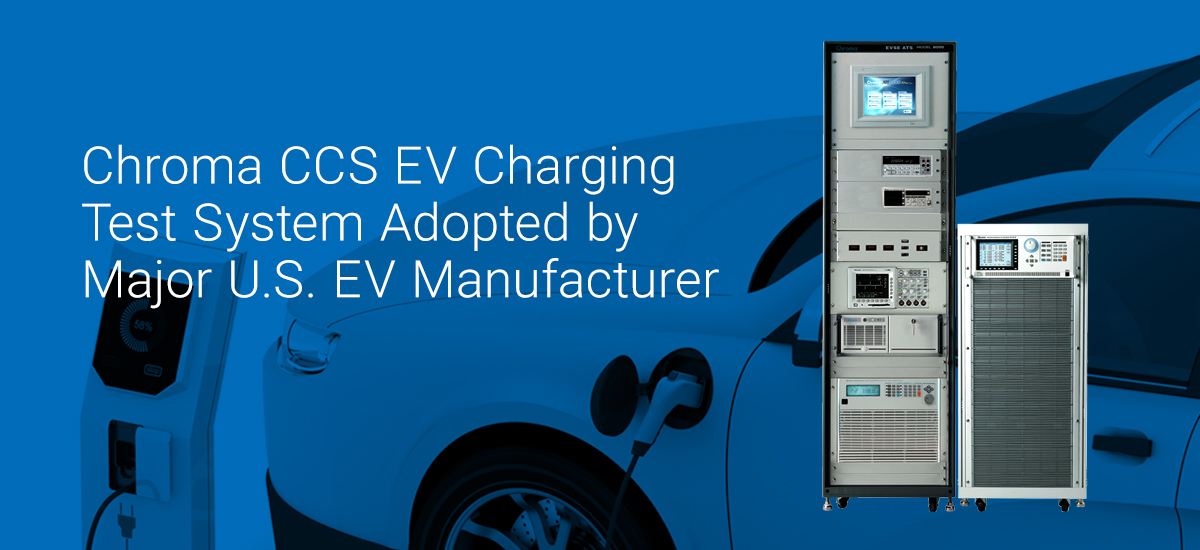

The automotive trends and obstacles that engineers face during design verification, functional test and mass production testing can be very difficult to navigate. This seminar has been put together to demonstrate the improvements made to EV testing performance with newly developed instruments, functional test systems, battery test and simulation systems. You will get an overview of the entire scope of work with reliable, precision instrumentation and systems including electrical safety testing for multiple applications.