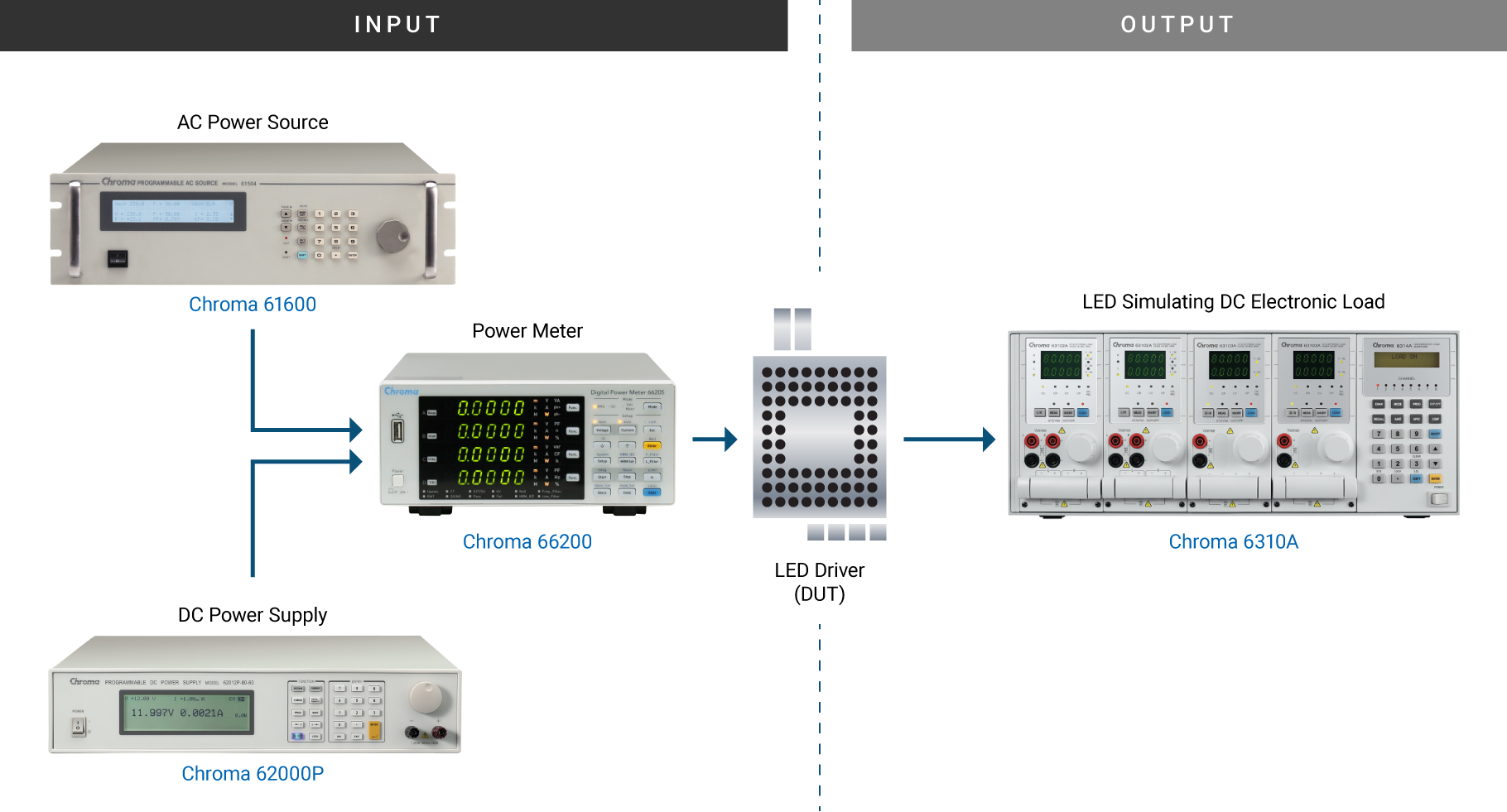

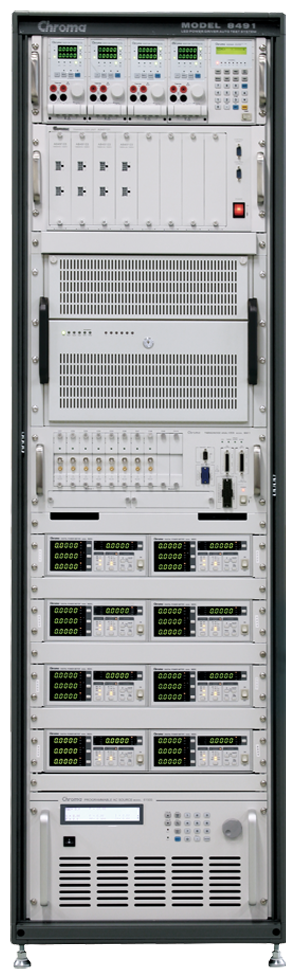

LED Power Driver Test System

Chroma C8000

This test system can test all the input and output conditions for LED Power Drivers consistently and accurately. Programmed routines for a variety of tests fully test the entire specifications for an LED Power Driver and can handle multiple measurements for multiple unit testing. Using Chroma’s Power Pro software, the system is easy to program and data collection for SPC requirements is built right into the software.

The Chroma C8000 ATS is equipped with optimized standard test items for LED driver testing (lighting & TV backlight). The user is only required to define the test conditions and specifications for the standard test items to perform the test.