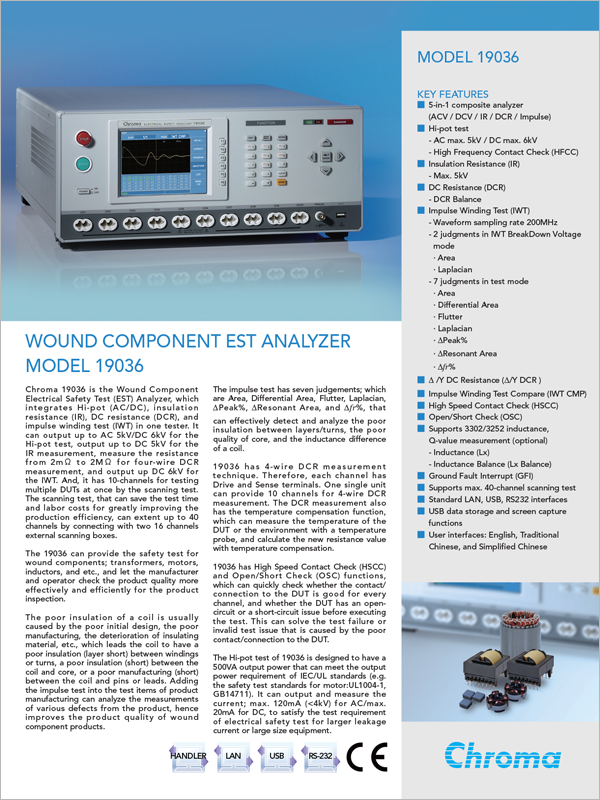

Exploring Wound Component EST Analyzer

Wound Component EST Analyzer

Chroma 19036

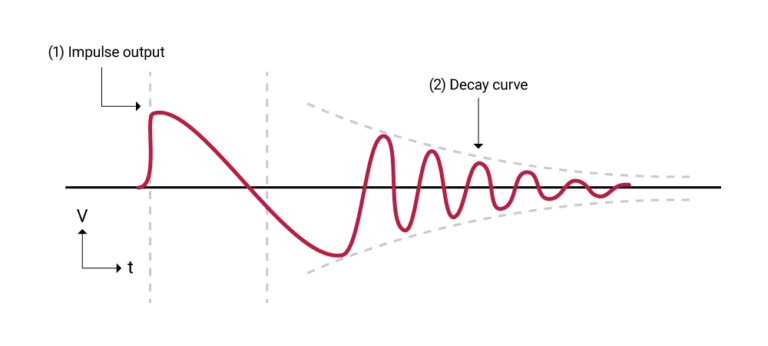

Impulse winding test imposes a non-destructive, high speed and low energy voltage impulse on the device under test for analysis and comparison

Mode (Model Specific)

AC / DC / IR /

Impulse (surge) / DCR

Channels

10 (up to 40 opt.)

Output Voltage

AC: 0.05~5kV

DC: 0.05~6kV

The industry’s first Wound Component Electrical Safety Test (EST) Analyzer that combines impulse winding, AC/DC hipot, insulation resistance and DC resistance test measurement functions. Chroma’s 19036 Wound Component EST Analyzer has 5kVac/ 6kVdc high voltage output, 5kV insulation resistance, 6kV layer short impulse voltage and 4-wire DC resistance measurement with a maximum output of up to 40 channels. Capable of outputting and measuring AC100mA/DC 20mA, Chroma’s 19036 is suitable for testing to high power motor standards such as UL 1004-1.

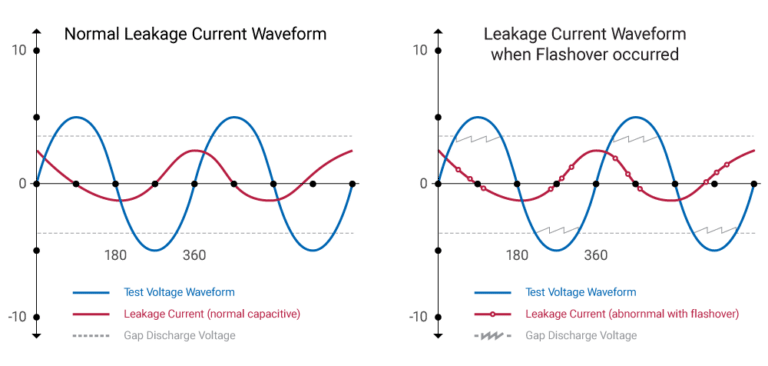

HI-POT Test Flashover Detection arc

Fast transient on detected leakage current is defined as flashover in hi-pot test. The 19036 has Flashover Detection as other Chroma safety test series. Flashover is nonsequential discharge generated by the inner or surface of insulation component which cause DUTs to lose original insulation feature, generated carbonation electrically conductive path and damages the product. As flashover cannot be detected by leakage current rms value, Flashover Detection is one of the inevitable inspection items in HV test.

Impulse Testing Overview

The impulse winding test is to impose a non-destructive, high speed and low energy voltage impulse on the DUT (Device Under Test) to analyze/compare the equivalent waveform of yield and defect products for good and no good judgement. The main function of impulse winding test is to discover the potential defects such as layer short, corona or partial discharge that is difficult to find in wound components in the early phase.

More Features

Support Max. 40

Channels Scanning Test

Easy to Program

User Interface

USB Waveform Storage

& Hard Copy Function

LAN, USB, and

RS232 Interfaces

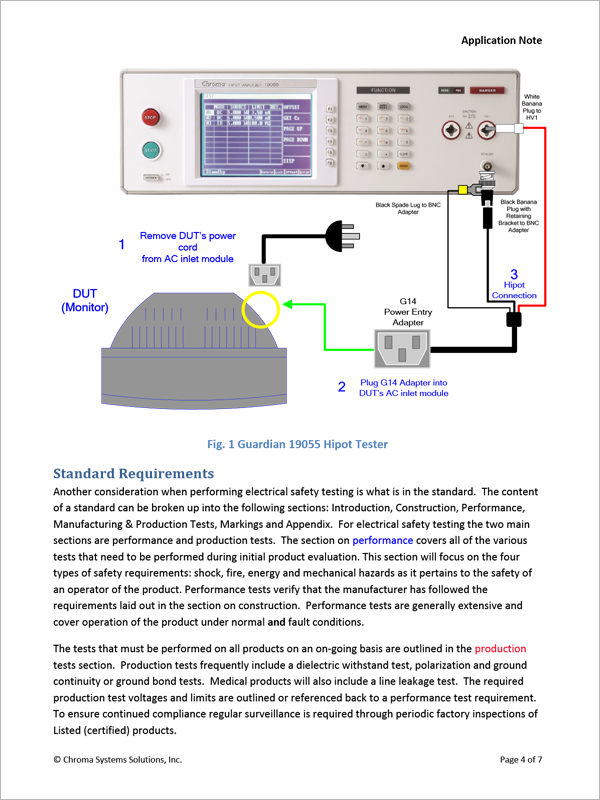

The motor standard such as UL 1004-1 requires high power safety tester. Chroma 19036 with the capability of outputting & measuring AC100mA/DC 20mA is suitable for testing large leakage current or big electrical safety equipment. Chroma 19036 as a comprehensive tester integrated with high power hipot test and other safety tests can bring the maximum benefit to the production line as well as to quality assurance. Its 500VA design is also compliant with the output power requirements of EC/UL.

Model Options

| Model | Description |

| 19036 | Wound Component EST Analyzer |

| Accessories | |

| A190359 | 16ch HV External Scanning BOX |

| 10544 | Softpanel Kit |

Watch

Stators, Transformers, Inductors: Solving Issues of Testing for Safety and Quality

This seminar covers some of the standards related to these components, test equipment, and test methods to comply with those safety and quality standards.

Chroma's 19036 Wound Component EST Analyzer

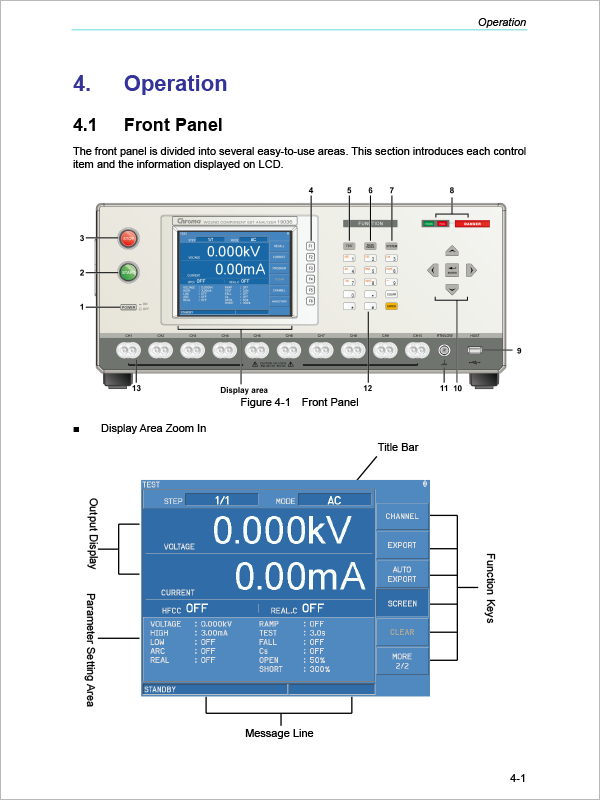

The Chroma 19036 is the industry’s first Wound Component Electrical Safety Test Analyzer that combines impulse winding (also known as surge testing), AC/DC hipot, insulation resistance, and DC resistance test measurement functions into one 10 channel unit.