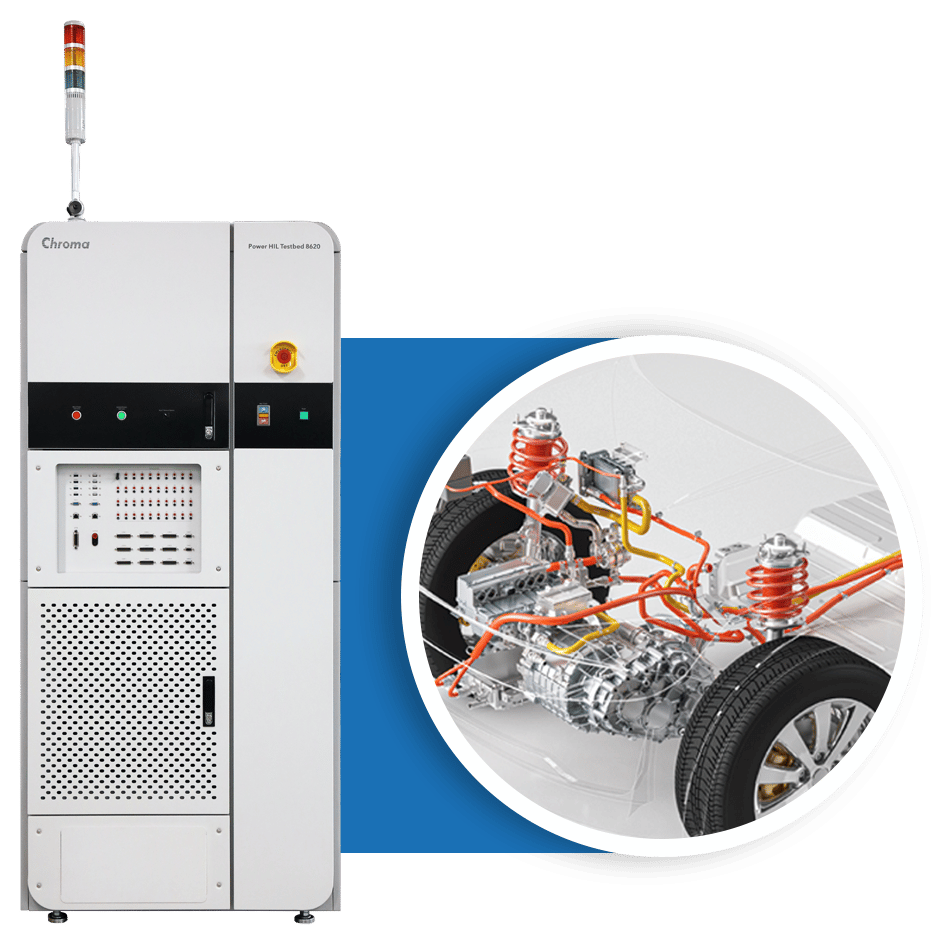

Exploring OBC & DC-DC Converter Power HIL Testbed

OBC & DC-DC Converter Power HIL Testbed

Chroma 8620

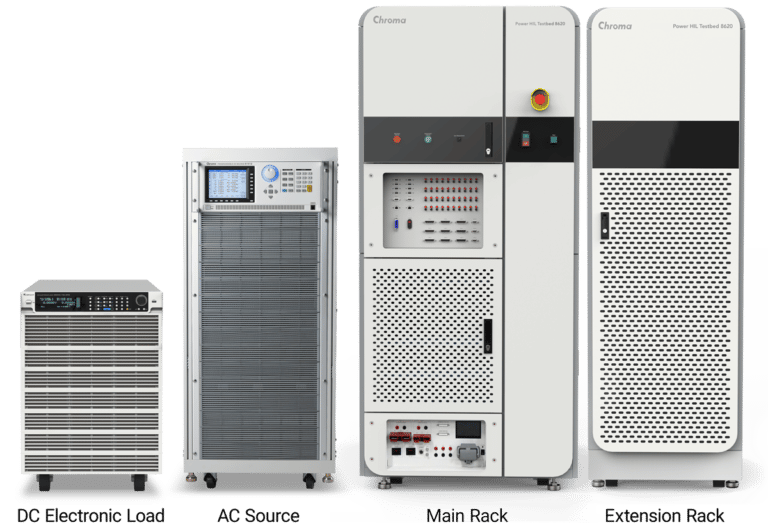

Designed for testing electric vehicle charging systems and powertrain components; supports customized hardware configuration, platform sharing, and expansion

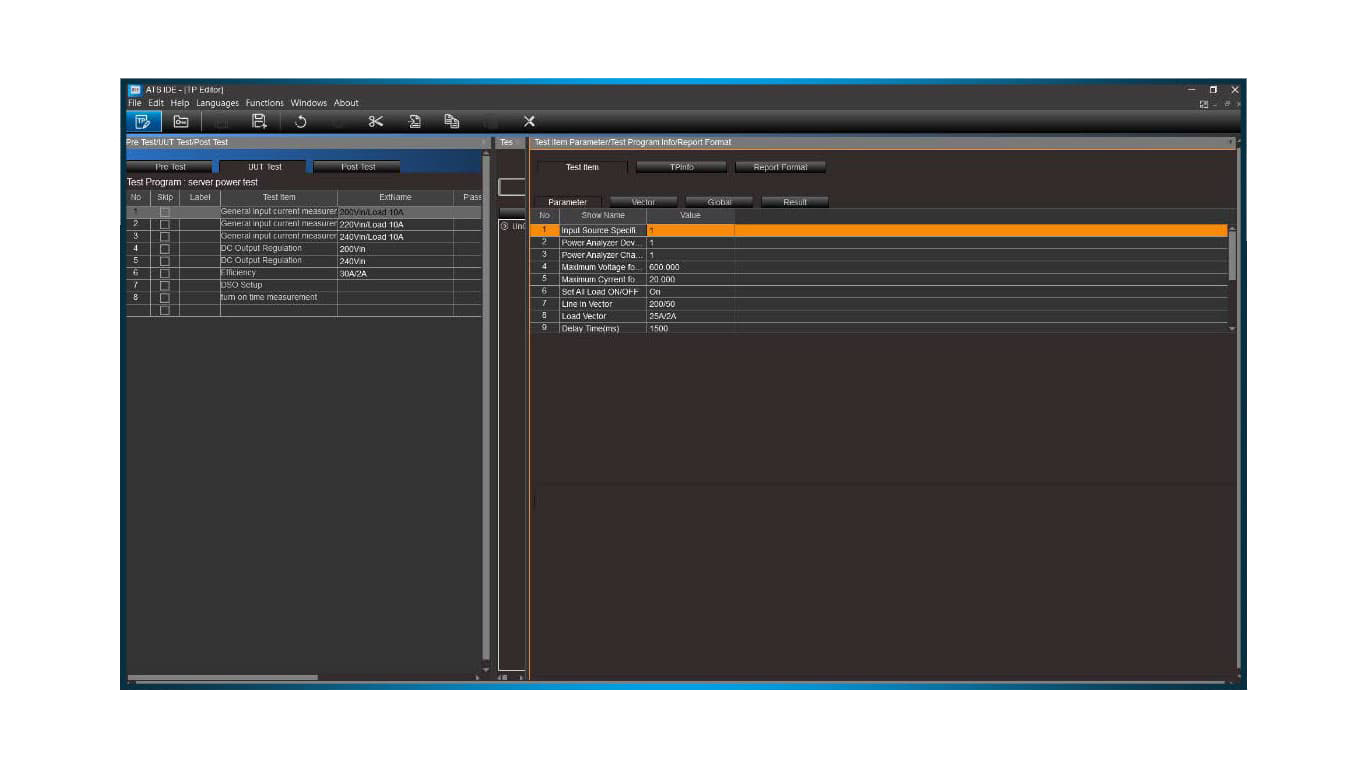

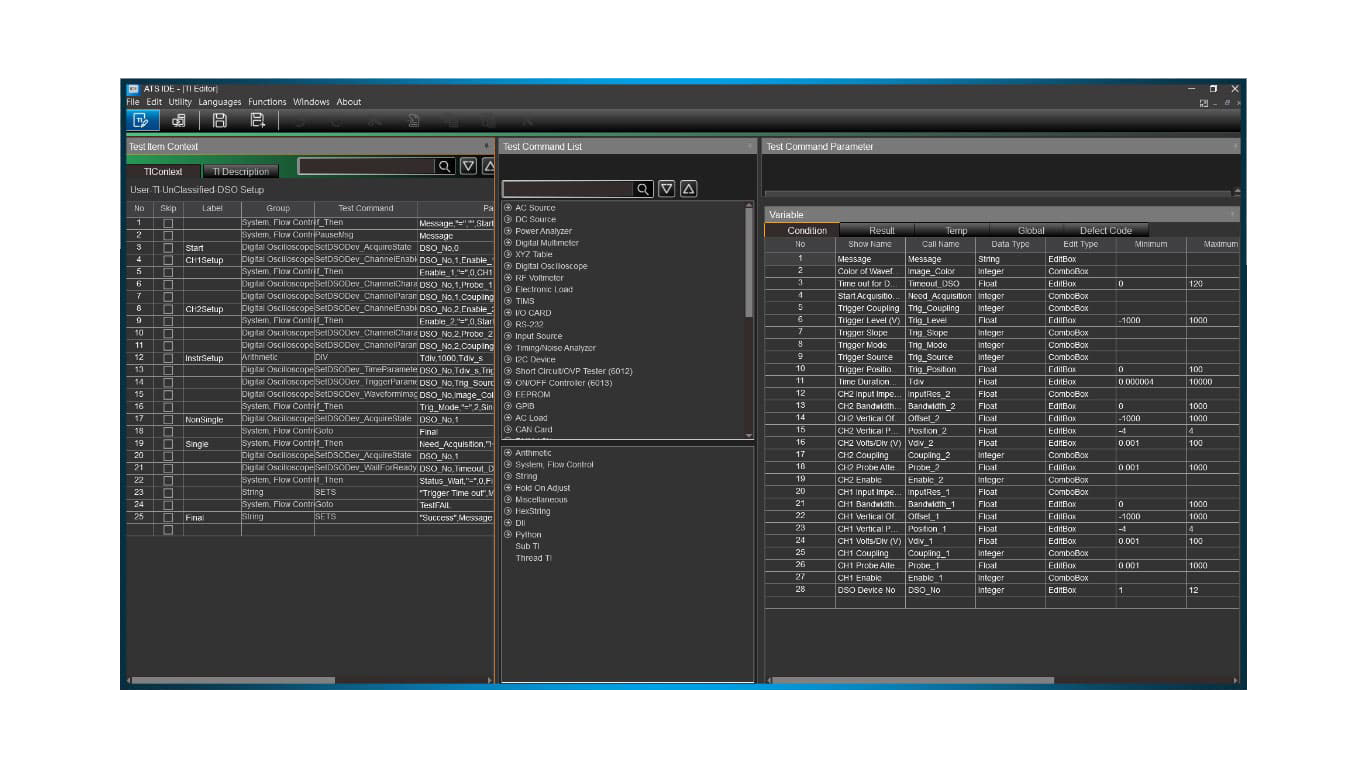

Chroma 8620 is specially designed for research and development of on-board chargers (OBC) or DC-DC converters. Its flexible software provides user interfaces for operation and monitoring of manual and automated test functions and automatically generates comprehensive test reports. Users can quickly conduct large numbers of repeated tests, improving test coverage and efficiency.

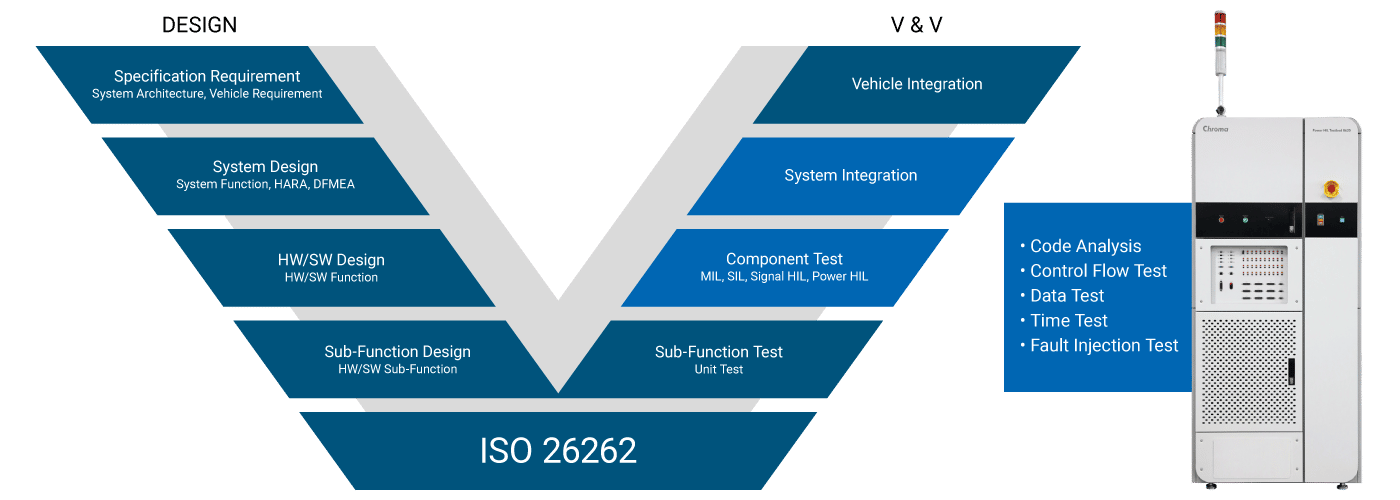

Vehicle Development Process and Test Requirements

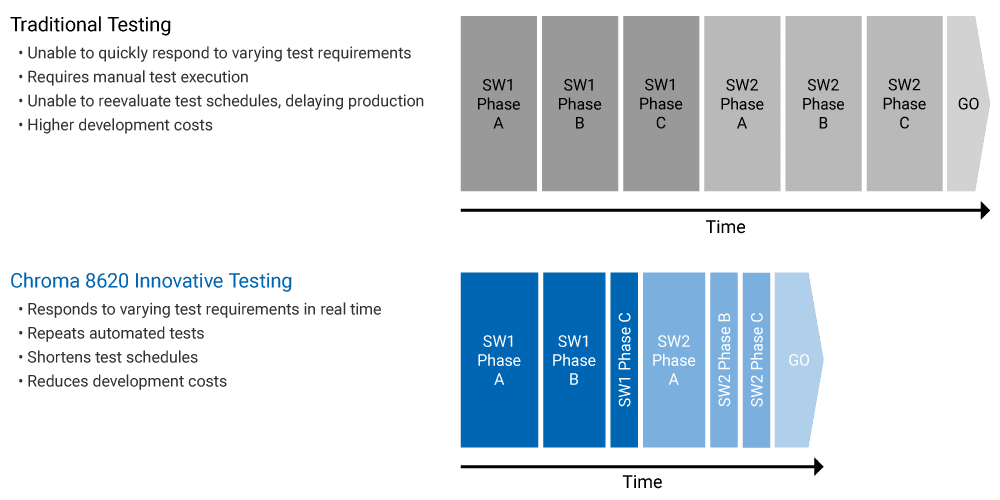

Chroma 8620 OBC and DC-DC Converter Power HIL Testbed supports the hardware-in-the-loop test from the ISO 26262 V-model for functional safety in the development of road vehicles. It includes failure mode, functional hazard analysis, and potential risk functions related to the OBC and DC-DC converter in the design stage of the V-model. Various vehicle conditions can be simulated and tested on the bench. Users can discover and correct problems early, well before entering real vehicle tests, which helps in obtaining ASIL (Automotive Safety Integrity Level) accreditation. The testbed allows for the expansion or replacement of peripheral equipment to meet the test requirements of different DUT specifications.

Also, by simply modifying existing programming, users can begin a new test project without starting from scratch. Chroma 8620 allows for highly repetitive automated tests and reduces possible errors caused by continuous manual programming of test specifications. Not only can this testbed reduce the number of tests and development costs, it also helps to shorten the test time and improve overall test efficiency.

Real-time Tracking: Hardware and Software Status

Chroma 8620 has an independent PLC monitoring system, which can track the running status of the system software and test hardware in real time. When an error occurs, the protection and warning mechanisms are activated to avoid damage to the equipment and the DUT. The flexible software platform allows users to load CAN HS/FD and LIN communications files as well as combine real-time systems, power and measurement equipment, and vehicle models. This provides easy to perform real-time dynamic tests on OBC and DC-DC converters. The user interfaces and automated test procedures are so flexible they can be edited even during the execution of manual or automated tests. Automated test functions support upper-level test software using an ASAM XIL interface. After the test procedure is completed, test reports are automatically generated for convenient review of test changes and results. While testing, the test data can also be recorded and accessed in TDMS, CVS, and Text formats, for additional analysis.

Both the user interfaces and auto test procedures allow repeated editing or copying into new projects, so users can adapt test plans and apply them to different DUTs or projects. Additionally, in auto test procedures, users can implement well-known languages such as LabVIEW, C/C++, Python, and .NET, to increase flexibility, reduce repetitive engineering, and improve overall development efficiency.

Optimized Test Items and User Interfaces

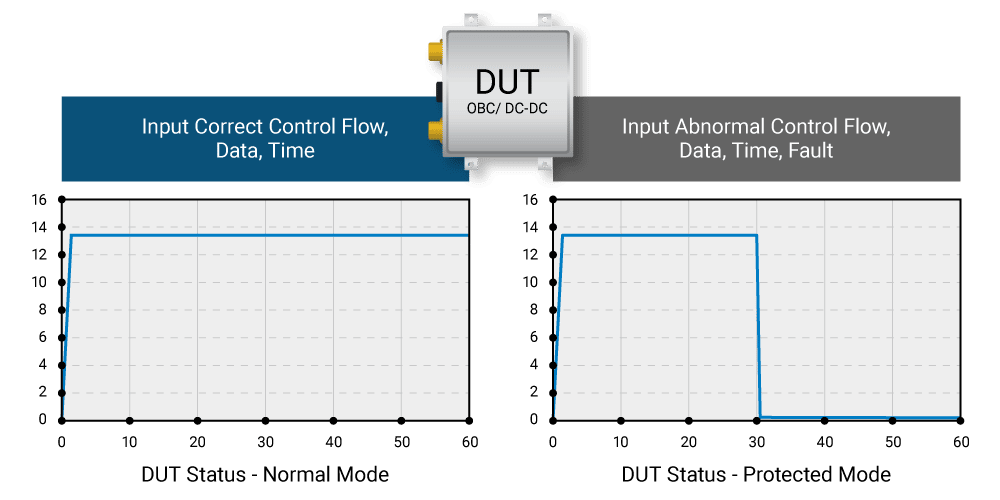

Chroma 8620 adapts automated test sequences through its software platform. Besides editing the test procedures for OBC and DC-DC converter regulations, it is customized for editing specific functions for different DUTs, including power-on and power-off, normal and abnormal communication, and signal fault injection, and other functions. Additionally, it simulates different control flows, time changes, and fault behaviors to increase the overall test coverage. Users can complete tests that cannot be performed on a real vehicle, prevent mistakes that could result in personal injury, and improve hazard analysis and risk assessment early on.

The customizable user interfaces are based on system integration of both power and measurement equipment, along with vehicle model types. Through the UI, users can execute tests and observe data content in real time, including parameter changes, chart display, signal statuses, etc., thus offering a great test experience and improved efficiency.

For functional testing, Chroma 8620 can simulate normal operating conditions of the DUT in a real vehicle environment. It can also simulate abnormal operating conditions, including communication abnormalities and signal faults (Open Circuit, Short to Ground, Short to Battery, Pin-to-Pin Short).

Model Options

8620

80619

61800 Series

61500 Series

62000H Series

62000D Series

62000P Series

62000L Series

63200A Series

66200 Series

5004 ATM

OBC and DC-DC Converter Power HIL Testbed

80619

AC EVSE Signal Emulator

61800 Series

Regenerative Grid Simulator

61500 Series

Programmable AC Power Source

62000H Series

Programmable DC Power Supply

62000D Series

Bidirectional DC Power Supply + Regenerative Load

62000P Series

Programmable DC Power Supply

62000L Series

Programmable Benchtop DC Power Supply

63200A Series

High Power DC Electronic Loads

66200 Series

Digital Power Meter

5004 ATM

IPC

PowerPro

Enterprise Wide Automation Software Platform

PowerPro 5 is designed for automated testing of various power conversion devices and power supplies. A wide selection of hardware options is available for integration, including programmable AC/ DC power supplies, electronic loads, digital multimeters, oscilloscopes, timing/noise analyzers, and short circuit and overvoltage protection testers. Combined with Chroma’s PowerPro 5 open software architecture, provides users with a versatile, powerful, and cost-effective automated testing system capable of meeting the testing needs of any form of power supply.

Watch

Battery Pack Power HIL Testbed-8610

Chroma 8610 Battery Pack Power HIL Testbed can both test functions on the traditional signal-level basis and verify actual power behavior, more completely covering the test range of EV high-power components.