AC/DC Hipot testers, Ground Bond, Insulation Resistance, Leakage Current

Hipot testers or dielectric withstand testing instruments are used for conducting electrical safety tests on electrical components and products to make certain they are in compliance with IEC, UL, TUV, CSA, EN, and other electrical safety requirements. In addition to general product and component testing, Chroma can help solve complex medical safety testing (60601-1) ensuring human safety and product reliability. New hipot and electronic safety test instruments (EST) purchased in North America are backed by a 2-year standard warranty.

Hipot Testers

Hipot testers determine the suitability of the dielectric or insulation barrier between hazardous and non-hazardous parts. Hipot testing (dielectric strength testing) appears in nearly every product safety standard and is a fundamental test used to check a fully assembled product as it exits the production line.

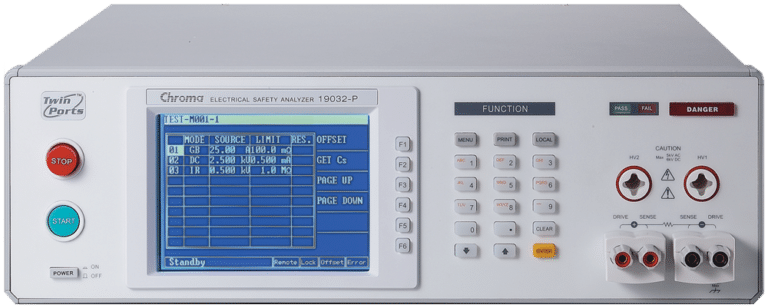

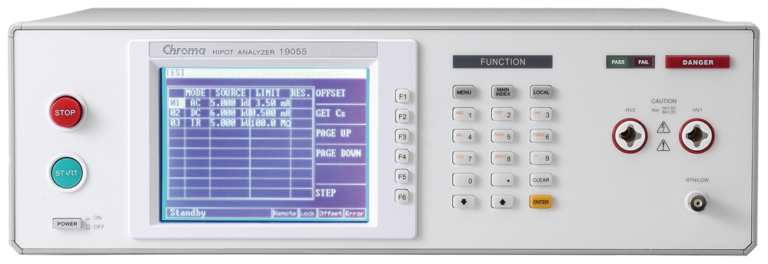

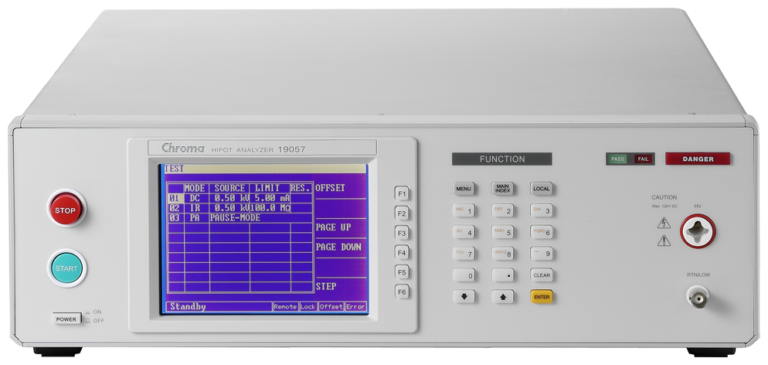

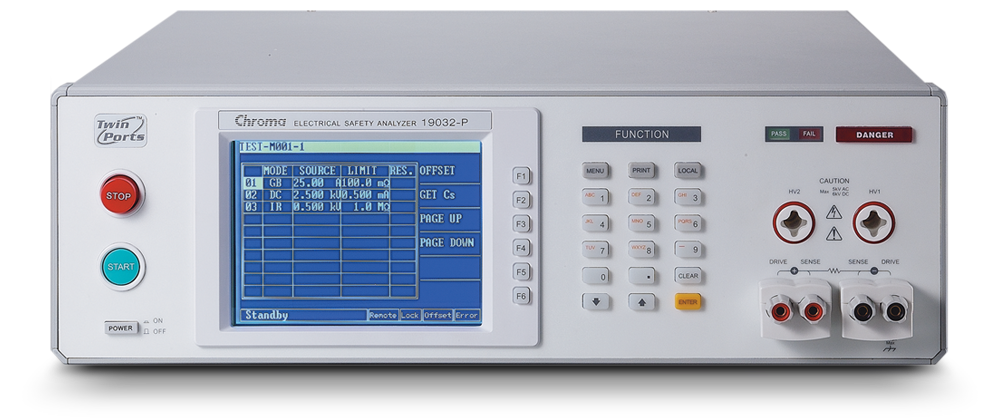

Advanced Hipot Analyzers

Chroma’s advanced hipot testers are used in quality assurance sample inspection testing, manufacturing testing, and development validation. Some example products are: Power cords, Household appliances (IEC 60335), Information technology products (IEC60950), Medical equipment (IEC60601), Lab/testing equipment, Video (IEC60065), and EMI filters.

Wound Component Hipot and Impulse Winding Testers

Quality verification testing for wound components including EV motors, servomotors, ascension motors, stators, transformers, heaters and solenoid valves. The Impulse Winding Test (WPT) discovers potential defects such as layer short, corona, and/or partial discharge which can go undetected during early phases of design and production.

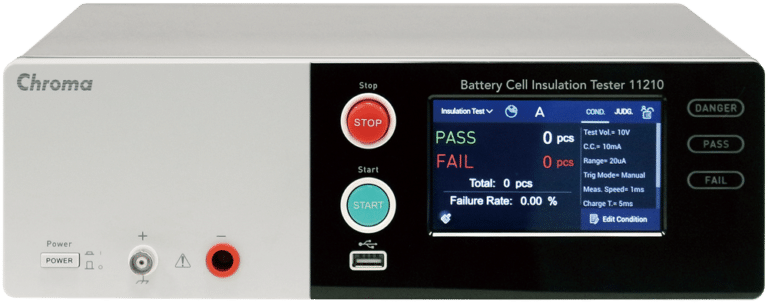

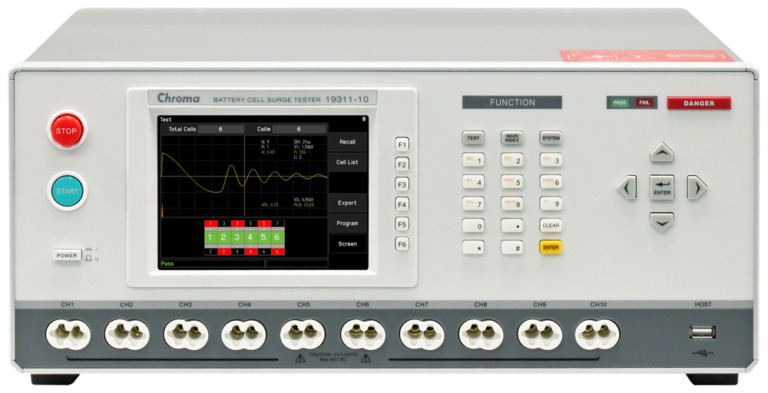

Battery Cell Safety Testers

A battery cell insulation tester accurately measures leakage current (LC) and insulation resistance(IR) of battery jelly-roll/dry-cell as well as other insulation materials. The tester includes partial discharge (PD) and flashover detection to identify defects and potential hazards. Our Surge Tester is designed for testing the insulation quality between the positive and negative plates of a lead-acid battery cell.

Ground Bond Testers

An economical instrument dedicated to measuring grounding resistance. Its compact form factor and easy to operate feature set supplies highly reliable and accurate test results.

Guardian Ground Bond Tester

Chroma 19572

Provides high current testing of ground continuity between chassis and power cord ground on a wide variety of electrical products and appliances

Electrical Safety Test Application Notes

Browse application notes on the topic of Electrical Safety Testing. Chroma’s application notes provide insight and context to assist test engineers with a particular technology, instrument, or application for their bench-top, R&D, design verification and/or ATE requirements and specifications.