Exploring Impulse Winding Tester

Impulse Winding Tester

Chroma 19305

Specifically designed to test winding components using a high-voltage charged micro capacitor and the coil under test, forming an RLC parallel resonant circuit.

Sampling Speed

10bit / 5ns (200MHz)

Inductance Test Range

More than 10uH

Remote Interface

LAN, USB, and RS232

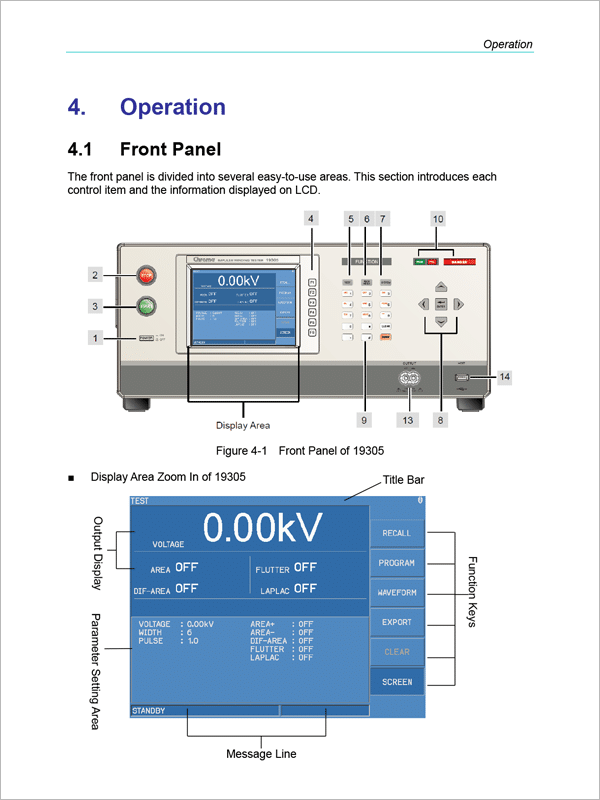

The Chroma 19305 series Impulse Winding Tester includes a single channel (19305) and a 10 channel output model (19305-10). Both models feature a 6kV impulse voltage and a 200MHz high-speed sampling rate which improves the sensitivity of discharge detection. To test more than 10uH, the tester is equipped with built-in functions such as Area Size Comparison, Differential Area Comparison, FLUTTER value, and LAPLACIAN value, which enable inspection of the coils for poor coil insulation.

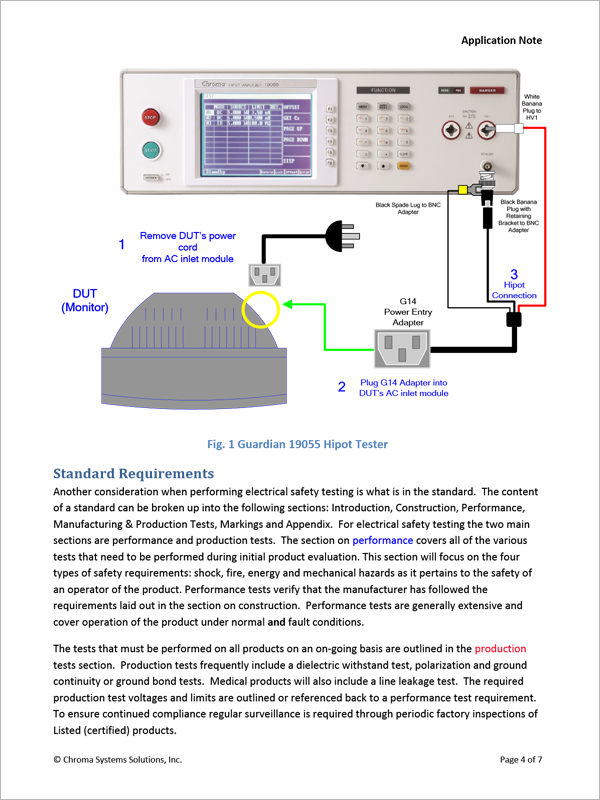

The testing of winding components includes electrical characteristics and safety withstand voltage tests. Poor insulation of coils is a common cause of layer short and output pin short-circuits during usage. This can result from bad initial design, poor processes, or deterioration of insulating materials. Therefore, including the coil layer short test in winding components is necessary.

The impulse winding test applies a non-destructive, high-speed, and low-energy voltage impulse to the device under test to analyze and compare the equivalent waveform of good and defective products for analysis. The main purpose of the impulse winding test is to identify potential defects such as layer short, corona, or partial discharge that are difficult to detect in wound components during early phases of production.

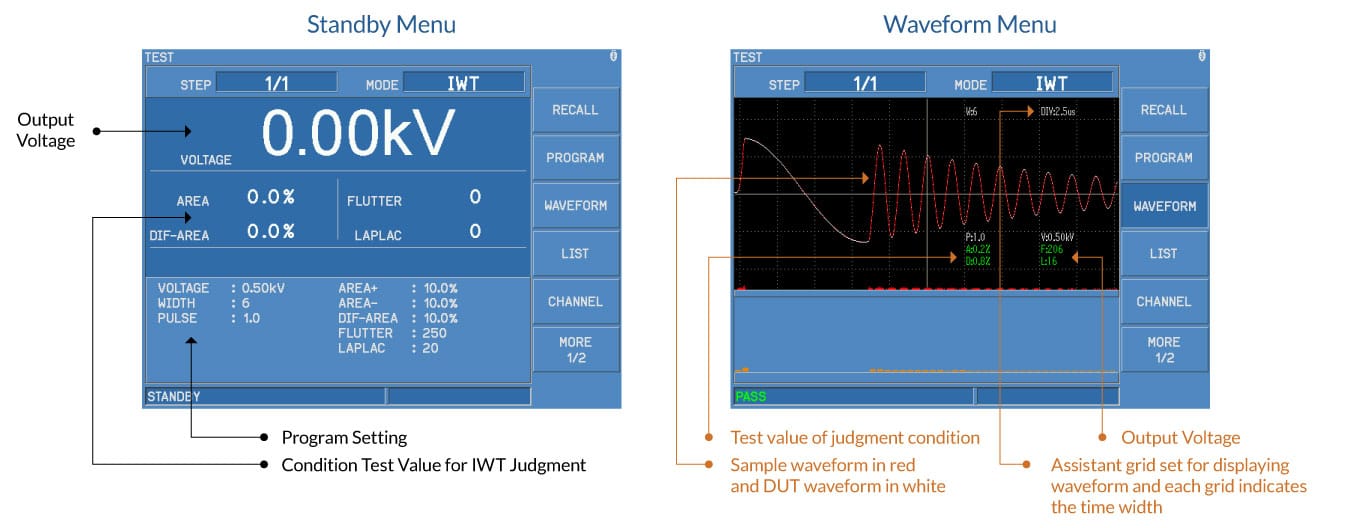

The Chroma 19305 series is specifically designed to test winding components using a high-voltage charged micro capacitor and the coil under test, forming an RLC parallel resonant circuit. By analyzing the oscillation decayed waveform through a high-speed and sophisticated sampling process technique, the tester can successfully detect coils with poor insulation. The analyzer can perform impulse tests on wound components such as motors and transformers. Implementing this test ensures not only reliable quality but also efficient product control in quality verification for wound components.

The Chroma 19305-10 provides a maximum of 10 channels output for multichannel scanning tests, which helps save time and labor costs for manufacturers.

16-40 Channels for Switch Testing

The A190359 scanner has 16 test channels and each of them can be set to H (High voltage, Hi), L (High voltage, Lo) or X (Open). The combination of 19305 and A190359 can apply high voltage to multiple points on a DUT, or apply high voltage to multiple DUTs at once. This setup reduces total test time and limits the need for operators to move leads in between tests, which helps decrease user error.

More Features

Breakdown Voltage Analysis Function

High Speed Test

Support Max.40 Channels Scanning Test

LAN, USB, and

RS232 Interfaces

Watch

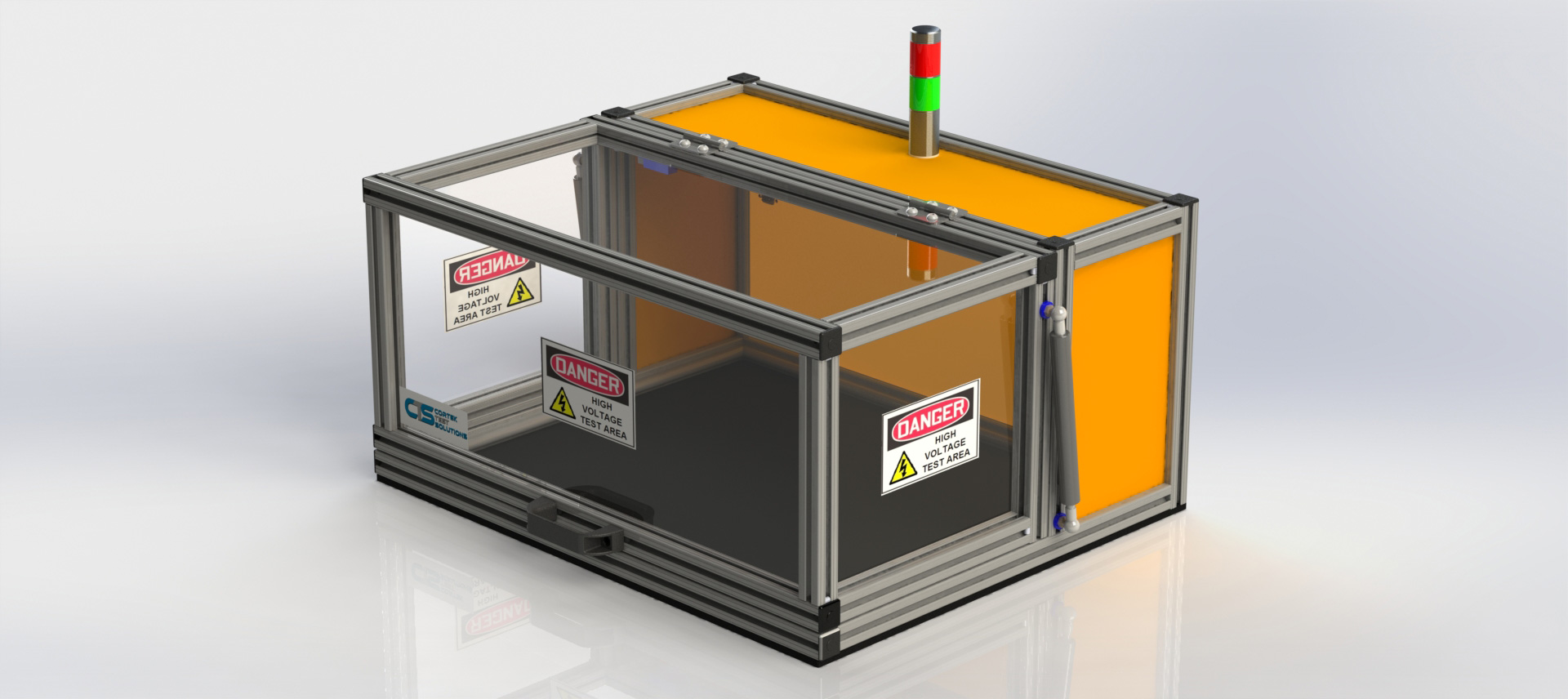

Webinar: Electrical Safety Testing 101

Get an overview of the basic principles of electrical safety testing.