Exploring Modular DC Power Supply

Modular DC Power Supply

Chroma 62000B

Unique features include a N+1 redundancy, high power densities, hot-swappable maintenance, remote ON/OFF and programmable control via the CAN bus for Burn-in and plating/electrolysis applications

Power Rating

up to 1.5kW per module; up to 120KW per system

Voltage Range

1~150V

Current Range

up to 2000A (System)

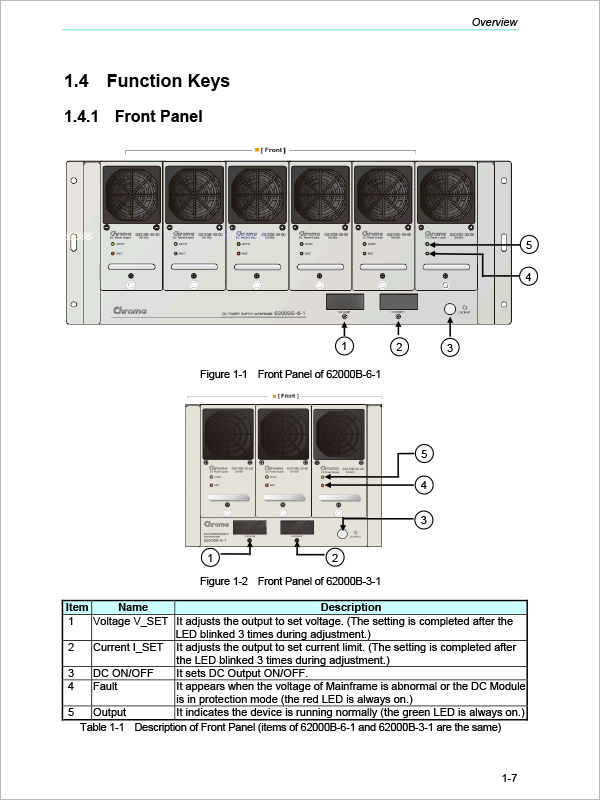

Chroma’s 62000B series of Modular DC Power Supplies offer 5 types of power module with ranging from 1V to 150V, current from 10A to 90A, and offers two mainframe type of six and three position. The six position mainframe can envelop in up to six power modules paralleled operation for 9KW power output. The 62000B can easily parallel up to 14 mainframes to 120KW with current sharing and CAN bus control for bulk power applications.

These instruments are designed for burn-in applications such as the LCD panels, DC-DC converters, power inverters, notebook computers, battery chargers and many other types of electronic devices.

Hot-Swap Operation

Equipped with N+1 redundancy and hot-swap functionality, the 62000B DC Power Supplies are most applicable for 24-hour non-stop applications such as SMD plating production lines, as well as product life burn-in test for IT products like DC converters, LCD backlight inverters and routers. For continuous operation applications the modular hot-swap design allows engineers to replace the failure unit on-site without shutting down the entire system.

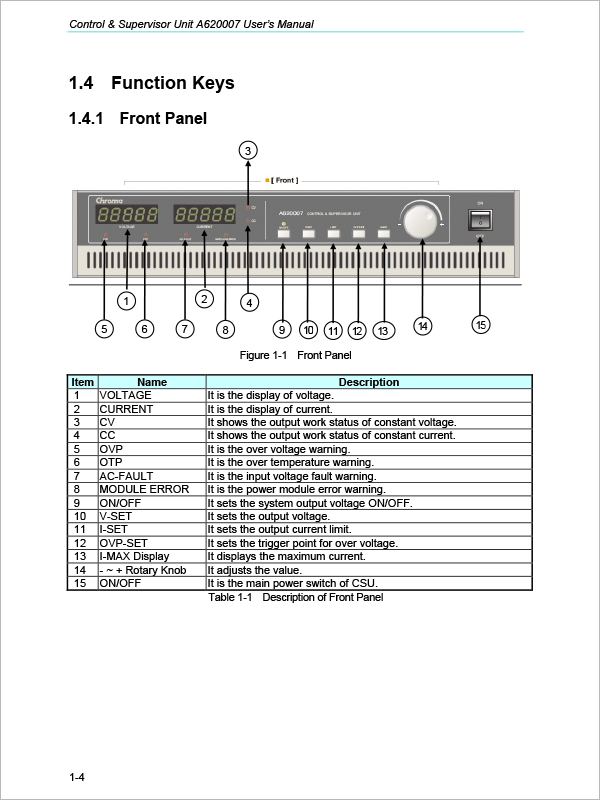

High Power Applications with CSU

The 62000B modular power supplies are capable of providing high power output up to 120KW/2000A with minimal specification degradation via CSU (Control & Supervisor Unit). Each chassis is designed to accommodate a maximum of 9KW and include current sharing capability to ensure system stability. In addition, for convenient control of even large power systems, a CSU is provided to set and display output and protection circuits via a standard CAN bus communication protocol.

More Features

High Power Density

Master/Slave

Parallel Control

Standard Analog

Programming Interface

Optional Graphic

User Interface

Modern power factor correction circuitry is incorporated in 62000B providing an input power factor above 0.98 to meet the IEC requirements. This PFC correction circuitry not only reduces the input current draw but also greatly reduces generation of input current harmonics. Optional graphic Soft Panels and CAN bus control allow for control and monitoring of the power system using an easy to use graphical interface.

Model Options

| Model | Description |

| 62015B-15-90 | DC Power Supply Module, 15V/90A/1350W |

| 62015B-30-50 | DC Power Supply Module, 30V/50A/1500W |

| 62015B-60-25 | DC Power Supply Module, 60V/25A/1500W |

| 62015B-80-18 | DC Power Supply Module, 80V/18A/1440W |

| 62015B-150-10 | DC Power Supply Module, 150V/10A/1500W |

| 62000B-3-1 | Three Position 62000B Mainframe |

| 62000B-6-1 | Six Position 62000B Mainframe |

| Accessories | ||

| A620007 | Control & Supervisor Unit | |

| G32 325500 | Rack mounting kit [62000B-3-1] | |

| A620010 | Rack Mount Kit [62000B-6-1] | |

| A620011 | Ethernet Interface [CSU] | |

| A620019 | USB Control Box [M/F & CSU] | |

| A620020 | GPIB Interface Control Box [62000B M/F & CSU] | |

| A620021 | Analog Interface Remote Control Box | |

| 7028 | Dual Channel PC CanBus Card | |

| 8191 | CAN Bus Interface s/Cable [62000B M/F] | |

| 10808 | Softpanels | |

| 8217 | USB to Canbus Interface | |

| G16066900 | Filler Panel for Model 62000B Mainframe | |

Watch

Webinar: DC Power Supplies with Transient and Auto-ranging capabilities

This seminar highlights key features and functions of our DC Power Supplies and the many applications they are being used for all over the world. Chroma programmable DC Power Supplies cover a wide range of power, voltage and current with advanced features for lab or rack-mounted applications.

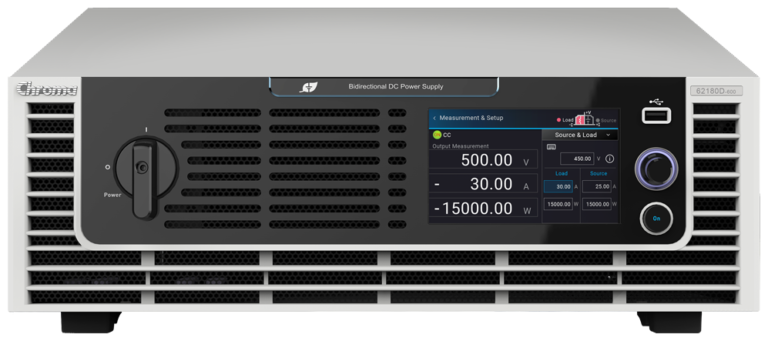

Related Products

Modular DC Power Supply

Chroma 62000B

up to 1.5kW per module; up to 120KW per system

1~150V

up to 2000A (System)

Unique features include a N+1 redundancy, high power densities, hot-swappable maintenance, remote ON/OFF and programmable control via the CAN bus for Burn-in and plating/electrolysis applications