Exploring Partial Discharge Tester – 19501-K

Partial Discharge Tester – 19501-K

Chroma 19501-K

Specifically designed for testing high voltage semiconductor components and high insulation materials.

Mode (Model Specific)

Partial Discharge Test

1-200 pC

Output Voltage

0.10 kV~10.00 kV, steps 0.01 kV

Remote Interface

LAN, USB, and RS232

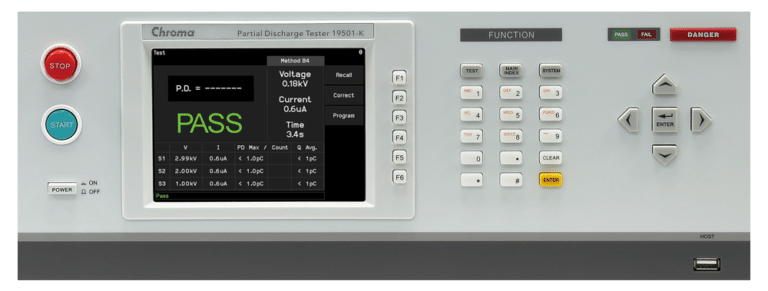

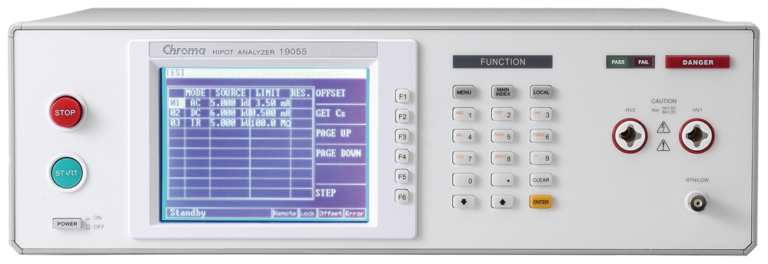

The Chroma 19501-K Partial Discharge Tester is an instrument equipped with AC hipot test and partial discharge detection functions, providing 0.1kV~10kV of AC output, 0.01μA~ 300μA of leakage current, and 1pC~2000pC partial discharge detect ion range for measurement. Chroma 19501-K Partial Discharge Tester is compliant to the IEC60270-1 standard in particular the partial discharge testing requirements for high voltage.

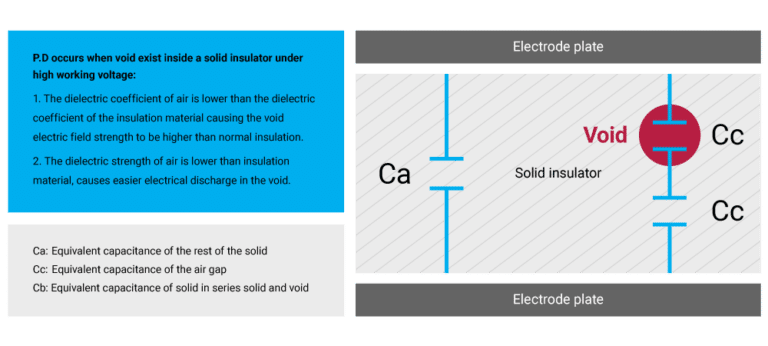

Partial Discharge

Partial Discharge is the local dielectric breakdown of a small portion of insulation systems, where the electric field strength exceeds the breakdown point of the insulation material; this does not bridge the space between two conductors.

The partial discharge tester applies voltage to the DUT under a certain condition to measure the apparent partial discharge (PD). Besides verifying its ability to withstand a transient high voltage (hipot test), it also verifies the insulation integrity at rated operating voltage. The partial discharge test can detect whether there are abnormal air gaps on the electrical components by applying a charge slightly above the maximum rated voltage. This also tests its long-term reliability under normal voltage conditions. Although, it is impossible to be 100% free of air gaps inside the insulation material during actual production, the IEC60747-5-5 optocoupler standard still defines that for partial discharge testing, the discharge capacity cannot exceed 5pC (qpd=5pC).

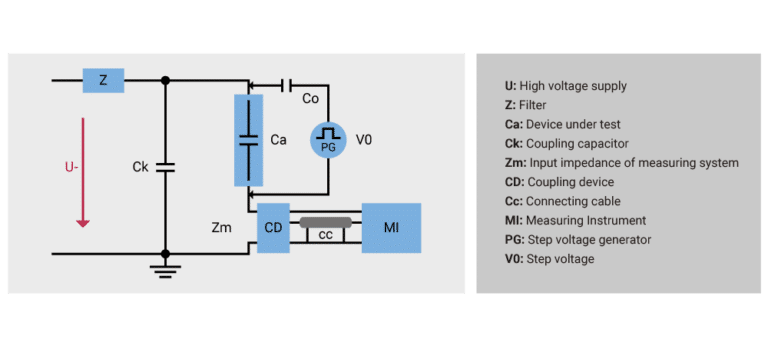

Partial Discharger Calibration

When using a partial discharger to calibrate the partial discharge tester for measuring micro discharge, the signal is very small and fast. Thus, the partial discharge tester has to be accurately calibrated before shipment to ensure the high frequency signal can be measured during discharge. The IEC60270-1 high voltage test standard, which explicitly states the calibration standards and methods for partial discharge, is conformed to developing the Chroma 19501-K partial discharge tester.

High Precision Measurement

The Chroma 19501-K is a high precision partial discharge tester equipped with 200pC and 2000pC two ranges to measure from 1pC to 2000pC, and the best resolution in range 200pC is 0.1pC. Its high accuracy measurement and intuitive display of measured results on the screen facilitate the assessment and analysis of small discharges for highly insulated objects.

More Features

Graphical

Editing

Anti-Interference

Structure Design

Three Stages

of Voltage Test

LAN, USB, and RS232

Remote Control Interface

Watch

Chroma Partial Discharge Tester

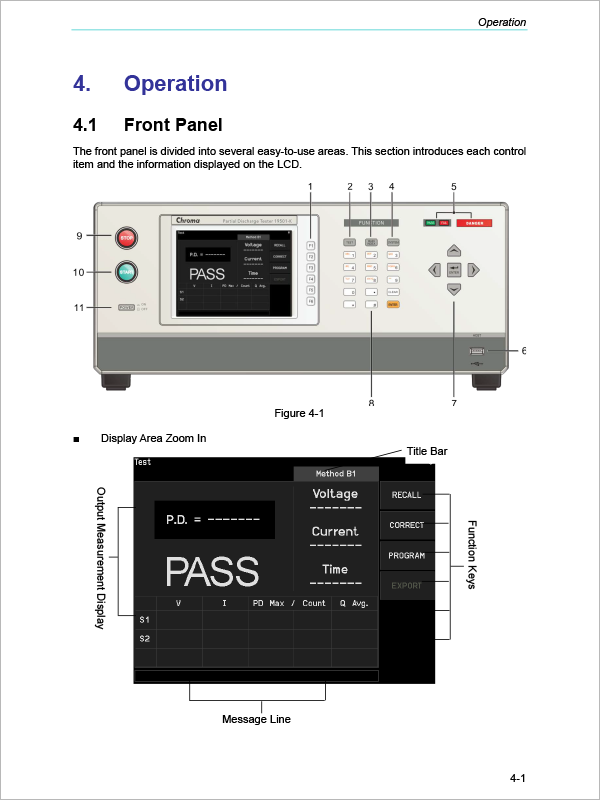

The product design is compliant to the IEC60270-1 standard in particular the partial discharge testing requirements for high voltage and embedded IEC60747-5-5 measuring methods can meet the production test requirements, providing a user-friendly operating interface.