Battery | Cell, Module, Pack Testing

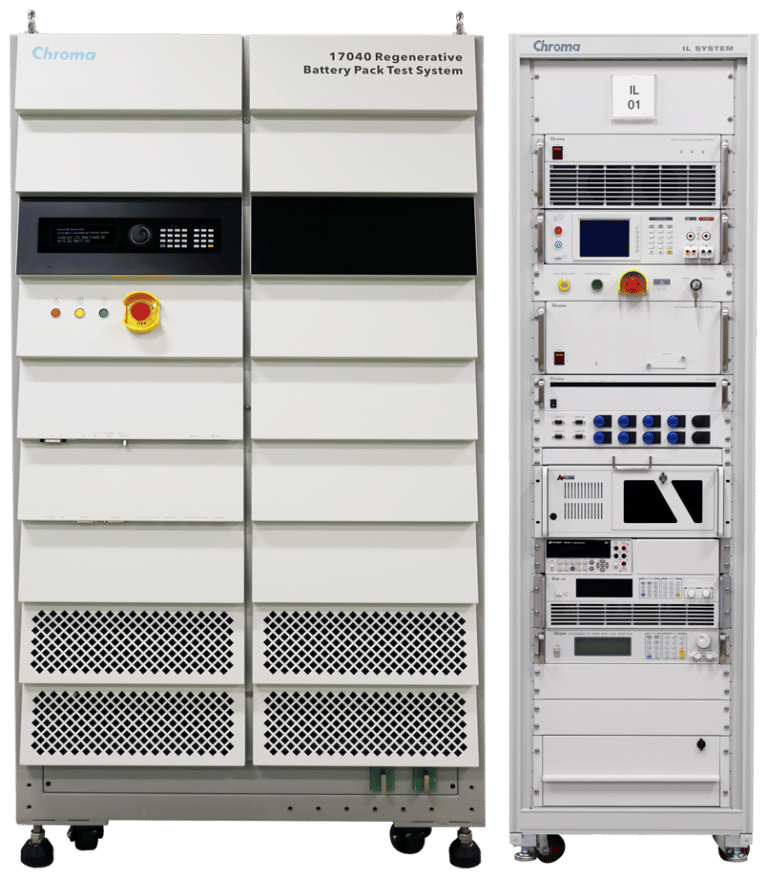

High precision, integrated battery cycling and energy storage test solutions designed for lithium ion and other battery chemistries. From R&D to end of line, we provide advanced battery test features, including regenerative discharge systems that recycle energy sourced by the battery back to the channels in the system or to the grid.

Battery Test Solutions

Chroma satisfies battery test requirements such as charge rate, discharge rate, state of charge (SOC), and state of health (SOH), and depth of discharge (DoD) with your need for accuracy in measuring voltage, current, temperature and power – statically and dynamically.

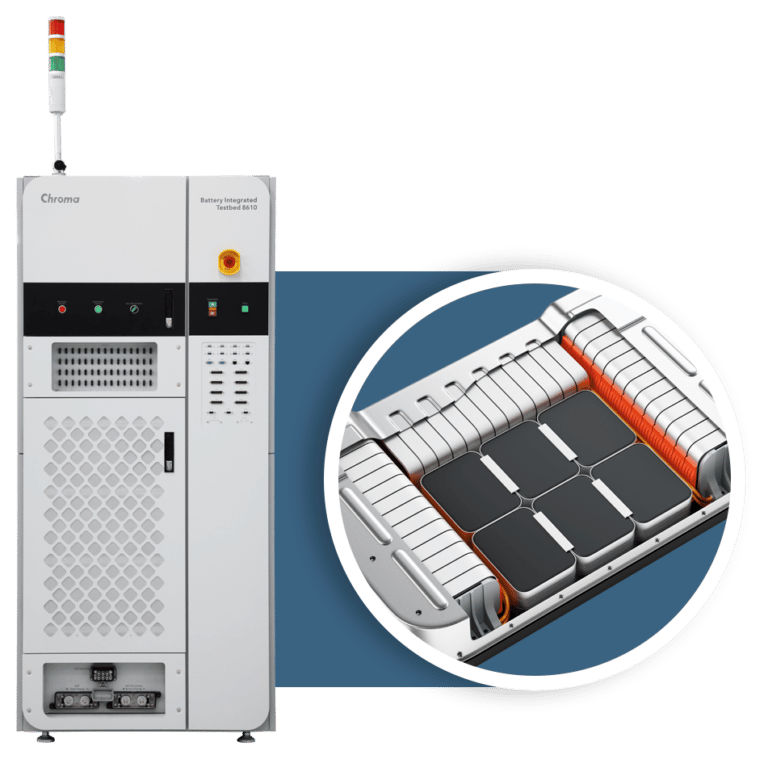

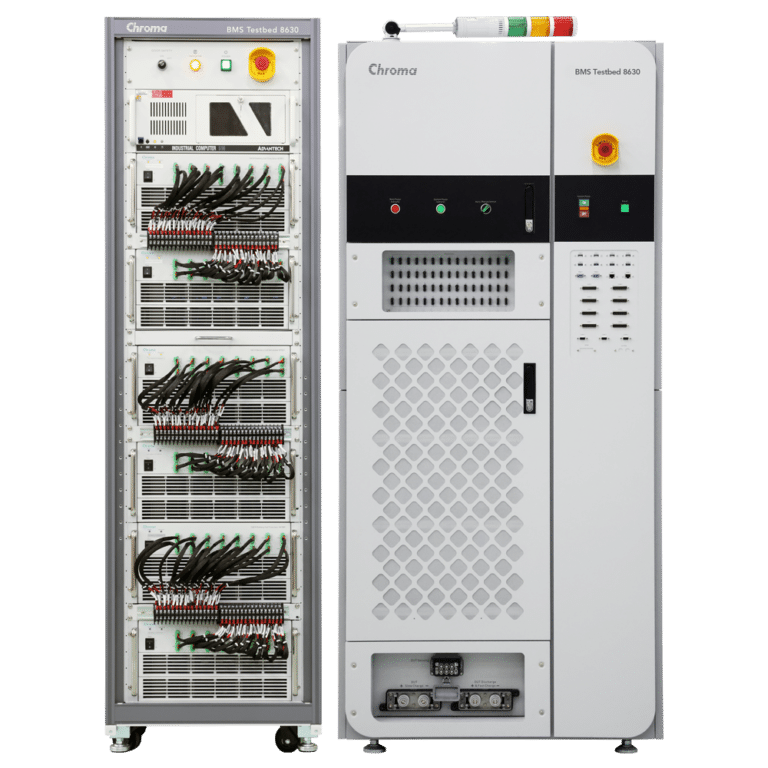

Battery Cycling: Cell, Module, Pack

Battery cell, module and pack level charge/discharge cycle testing solutions designed to provide high accuracy measurement with advanced features. Most of our solutions are regenerative – so energy sourced by the battery back is recycled back to the channels in the system or to the grid.

Battery Simulation

Battery simulation software for testing battery-connected devices in all applications to confirm if the device under test in performing as intended. Battery state is simulated if the battery is unavailable for testing, which eliminates waiting for the charge/discharge of an actual battery. Real-time test results include voltage, current, power, SOC%, charge/discharge state, and capacity.

Fuel Cell Testing

Fuel cells produce power by combining hydrogen fuel and oxygen electro-chemically and are extremely efficient and environmentally friendly. Chroma’s battery test platforms are engineered and well-equipped to support fuel cell research and design validation for efficiency, power, and characteristics.

Ultra/Super Capacitor

Chroma offers ultra and super capacitor charge/discharge testing systems with high precision output and measurement up to 0.02%. Satisfy IEC 62391 EDLC test requirements with a high sampling rate of 10ms. The modularized multi-channel architecture offers both flexibility and expand-ability, catering to cycle test requirements.

Battery Test Systems

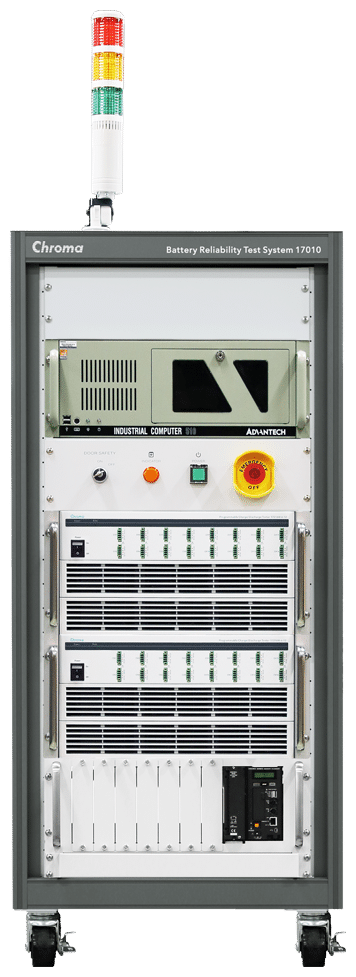

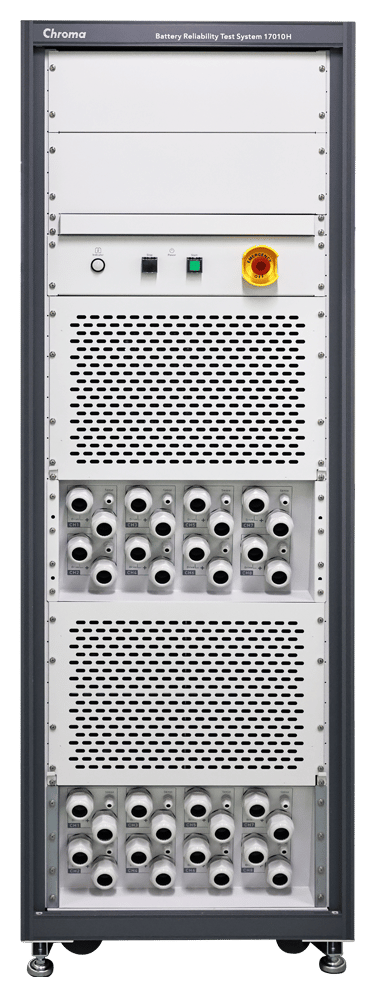

Battery Reliability Test System

Chroma 17010

Up to ±0.015% of full scale

Up to 100µS

Up to 10mS

Chroma’s Battery & Reliability Test System is a high-precision system designed specifically for testing lithium-ion battery (LIB) cells, electric double-layer capacitors (EDLCs), and lithium-ion capacitors (LICs).

Battery Pack ATS

Chroma 8720

5kW ~ 350kW

0V~900V

0A~1000A

Test the battery packs in end of line (EOL) production for a comprehensive Pass/Fail check, including mechanism assembly, pressure insulation, BMS communication, internal high voltage relay parts, battery balance, and temperature distribution, etc.

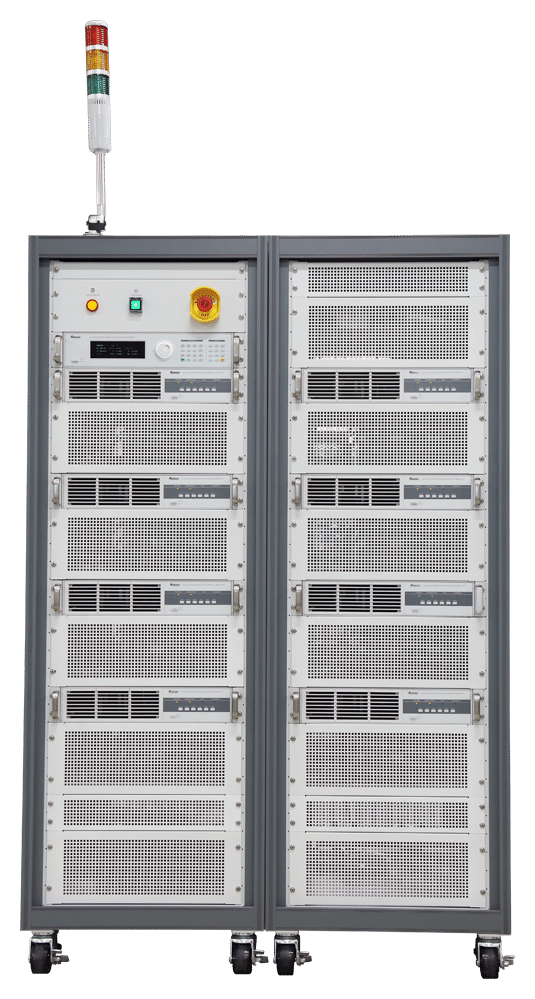

Battery Cell Formation Turnkey Solution

Chroma 17000

100kW*14, 200kW, 200kW*14, 300kW*14

5~850V, 100~1700V

0.1%F.S.

With built-in parallel channels and dynamic profile simulation functions; parallel capability maximizes the charge and discharge current and power, increasing the efficiency and flexibility of equipment utilization

Featured Articles

Available for Download

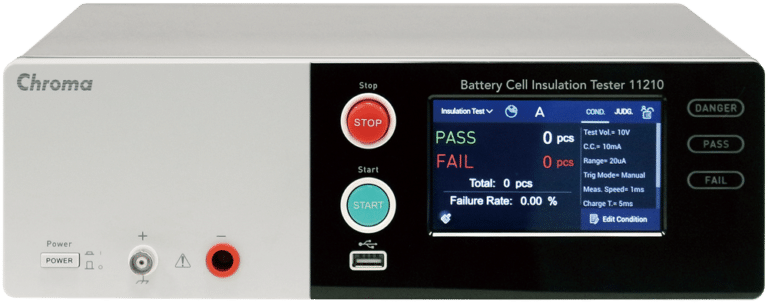

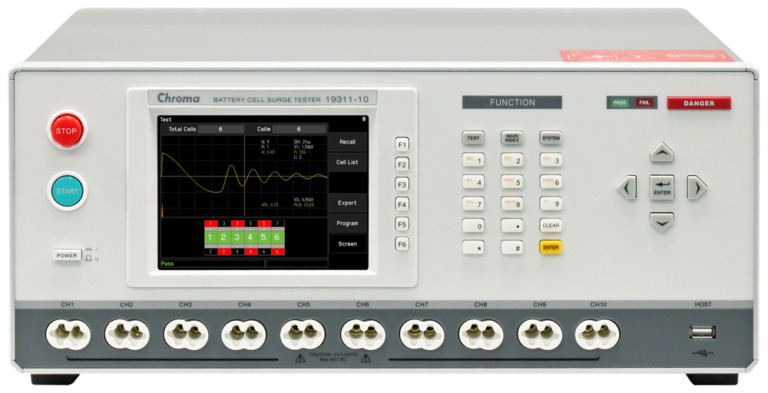

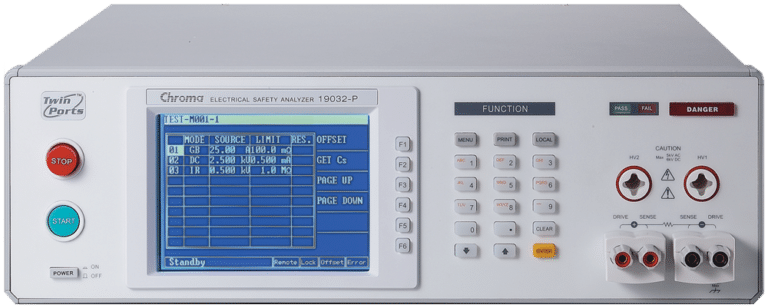

Battery Safety Testing

Our electrical safety testers support AC/DC hipot, leakage current (LC), insulation resistance (IR), and partial discharge (PD) at very high speed and accuracy to ensure the quality and safety of cells and modules before they go to the next level of production.

Electrical Safety Testers

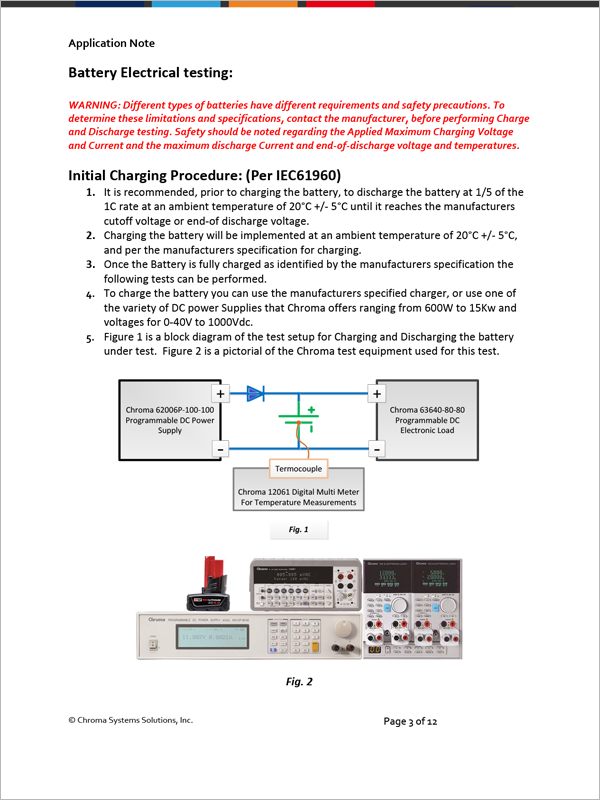

A Better Insulation Test: Decreasing Risk of Electrical Shorts in Lithium Ion Battery Cells

This video covers new testing procedures and equipment to monitor voltage and current in order to detect minor partial discharge or flashover inside the cell resulting in lower risk to the manufacturer and end user.

Software and SoftPanels

Battery Pro

Battery Pro is an intuitive, multi-channel test software platform designed for cell to pack level charge-discharge testing with real-time monitoring.

Power Pro

Designed for power conversion applications, PowerPro provides an editable library of over 35 pre-written commonly used tests.

Battery Simulator

Our Battery Simulation software is used to validate device functions during development in lieu of an actual battery or batteries.

Battery LEx

Create up to 500 projects and construct corresponding test plans according to different DUT types or requirements.

Decreasing Risk of Electrical Shorts in Lithium-Ion Battery Cells

This paper is a must read for cell manufacturers who are concerned about the quality of their battery cells and reducing the risk of battery fire before the cell reaches the end user.