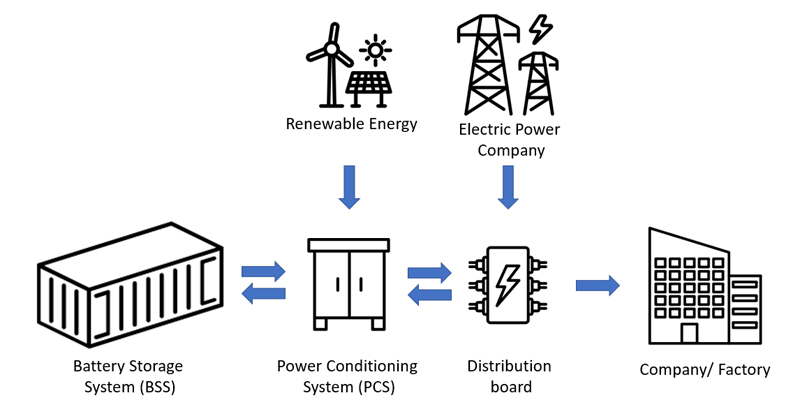

The increasing severity of climate change is driving a surge in demand for green energy. Renewable energy sources such as solar and wind power have already become an indispensable component of the energy supply. At the same time, market demand for high-efficiency energy storage systems (ESS) is also rising steeply. For successful deployment of these systems, the cooperation and integration between the battery and the Power Conditioning System (PCS) poses a particularly critical challenge.

The PCS is one of the core components of the ESS, and its performance and stability are crucial to the overall operation of the system. PCS equipped with Automatic Frequency Control (AFC) functionality also play a critical role in the electric power system. They can monitor changes in the grid’s frequency and rapidly output electrical power to stabilize the power system when the frequency is too low. Conversely, when the frequency is too high, they absorb excess power to restore frequency balance.

Energy storage systems have important and specific parameters for PCS performance, such as a charge and discharge response times not exceeding 0.5 seconds, a minimum sustained runtime of 15 minutes, and a system round-trip efficiency of over 85%. Therefore, PCS need to undergo a range of comprehensive tests, including charge/discharge testing, efficiency testing, and anti-islanding protection testing, to detect and address potential issues that may affect system stability at an early stage. By adding a battery simulator to the setup, test engineers can achieve significant gains in product validation efficiency.

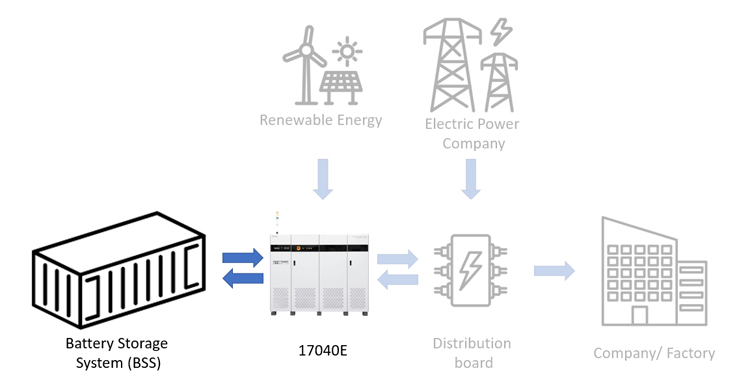

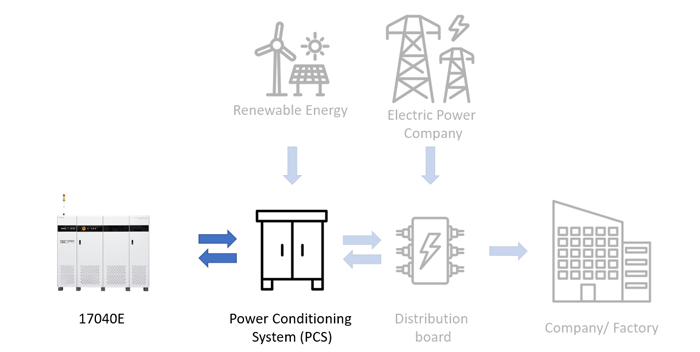

The Chroma 17040E Regenerative Battery Charge-Discharge Test System is a multifunctional instrument that can not only perform charge-discharge testing of battery packs, but also serve as a simulator that emulates the behavior of the battery. Offering both high voltage (1700V) and low voltage (850V) operation, the system provides high-precision voltage range control as well as four voltage and current measurement ranges —1700V/1200V/600V/150V and 400A/200A/100A/50A— making it suitable for a wide range of application scenarios.

With Chroma’s Battery Simulator SoftPanel software, users can input voltage-capacity/SOC curves through the curve function, allowing them to determine the conversion efficiency and usage state of the PCS under different working voltage ranges of the battery. The battery simulator allows precise control of the voltage without having to wait for the battery to actually charge and discharge, and has a high degree of repeatability resulting in improved test efficiency. Additionally, the equipment can simulate abnormal battery voltage conditions such as over-charging and over-discharging to verify the PCS’s response strategies in abnormal situations. Suitable for grid-connected ESS as well as residential and commercial ESS, this solution meets the needs of a wide range of applications and provides ideal equipment for PCS verification.

Successful integration between PCS and battery is crucial to ensure the smooth operation of energy storage systems. Chroma provides a range of solutions, including the 17040E battery simulator and the 61800 series grid simulators, and integrates them into an automated testing system for PCS, offering a comprehensive solution to safeguard PCS quality and meet the growing market demand. This solution has already found favor among ESS manufacturers and has been successfully adopted by leading laboratories for ESS certification purposes.