Exploring Regenerative Battery Pack Test System

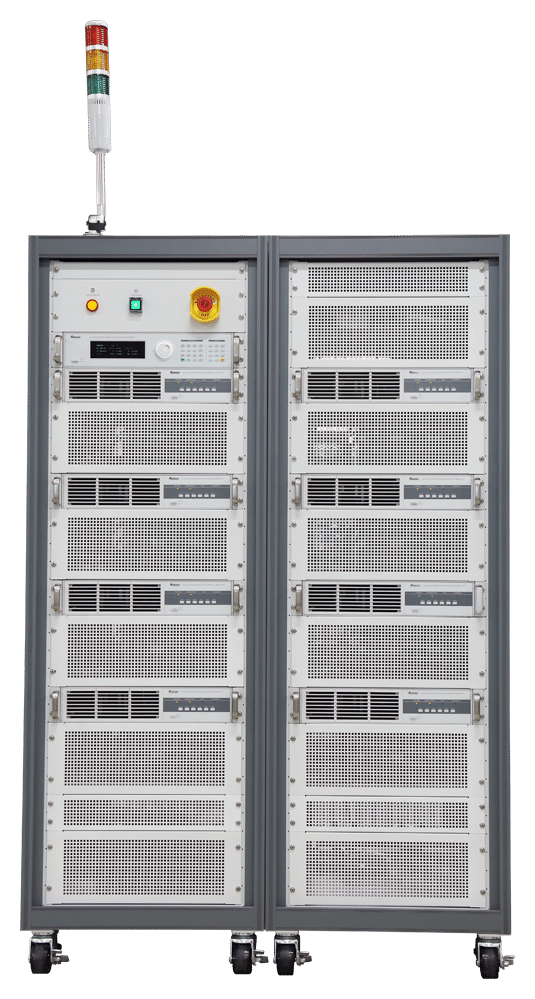

Regenerative Battery Pack Test System

Chroma 17020E

High precision system specifically designed for secondary battery module and pack testing

Power Range

10kW / 20kW / 30kW / 40kW / 50kW / 60kW / 70kW / 80kW per channel

Voltage Range

60V / 100V / 200V

Current Range

100A / 200A / 300A / 400A / 500A / 600A / 700A / 800A per channel

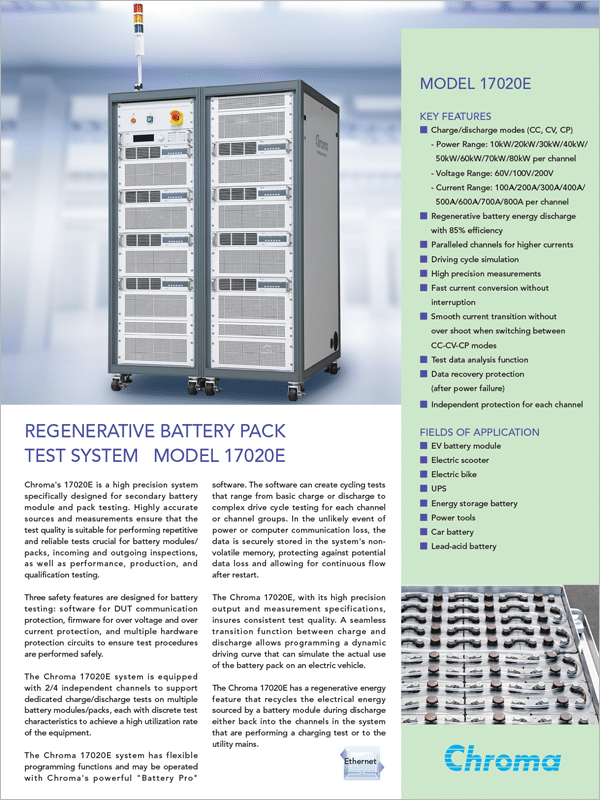

Chroma’s 17020E is a high precision system specifically designed for secondary battery module and pack testing. Highly accurate sources and measurements ensure that the test quality is suitable for performing repetitive and reliable tests crucial for battery modules/ packs, incoming and outgoing inspections, as well as performance, production, and qualification testing.

Three safety features are designed for battery testing: software for DUT communication protection, firmware for over voltage and over current protection, and multiple hardware protection circuits to ensure test procedures are performed safely. The Chroma 17020E system is equipped with 2/4 independent channels to support dedicated charge/discharge tests on multiple battery modules/packs, each with discrete test characteristics to achieve a high utilization rate of the equipment.

The Chroma 17020E system has flexible programming functions and may be operated with Chroma’s powerful “Battery Pro” software. The software can create cycling tests that range from basic charge or discharge to complex drive cycle testing for each channel or channel groups. In the unlikely event of power or computer communication loss, the data is securely stored in the system’s nonvolatile memory, protecting against potential data loss and allowing for continuous flow after restart.

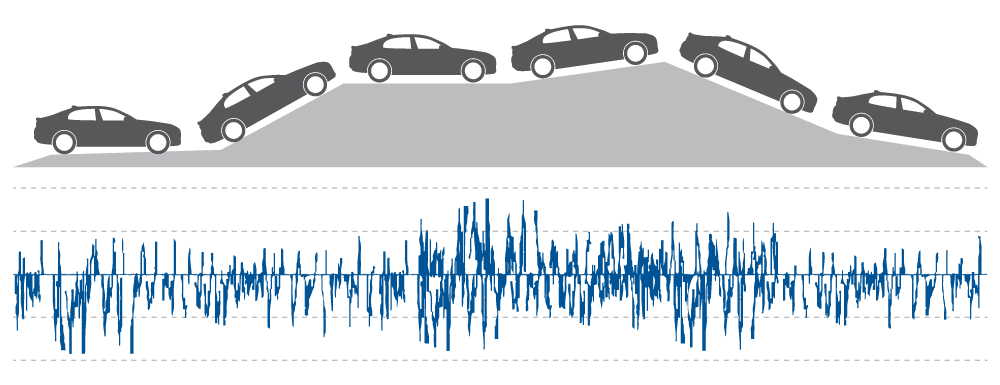

The Chroma 17020E, with its high precision output and measurement specifications, insures consistent test quality. A seamless transition function between charge and discharge allows programming a dynamic driving curve that can simulate the actual use of the battery pack on an electric vehicle. The Chroma 17020E has a regenerative energy feature that recycles the electrical energy sourced by a battery module during discharge either back into the channels in the system that are performing a charging test or to the utility mains.

Key Features

Security- Reinforce Risk Management

- Ability to directly input test, cut-off, and protection criteria to a charging/discharging device to achieve multi-layer protection through internal software and hardware

- Ability to integrate external hardware to get real-time monitoring parameters from a Battery Management System Data Communication Unit (BMS), Data Logger, Thermal Chamber, and I/O signals to execute warning/cut-off/ power off protection

- Ability to monitor various voltage and temperature values of battery packs throughreadings from BMS and measurements on Data Logger; also able to make fast decisions and trigger protection based on set values

- Built-in multiple warning and protection modes : OVP, UVP, OTP, WIR_LOSS, CAL_ERR, POW_ERR, RMT_RVS

Precision- Improve Product Quality

- High frequency sampling measurement technology: Max. sampling rate 50kHz to ensure dynamic measurement accuracy

- Voltage accuracy: ±(0.02% of rdg. ± 0.02% of F.S.)

- Current accuracy: ±(0.1% rdg.+ 0.05% rng.)

- Quick response test technology: 50ms (-90% to 90%) current slew rate applicable for various test applications

- Supports dynamic driving profile simulation (waveform), which simulates the current and power state of real driving conditions to comply with the NEDC, FUDS and HPPC standards

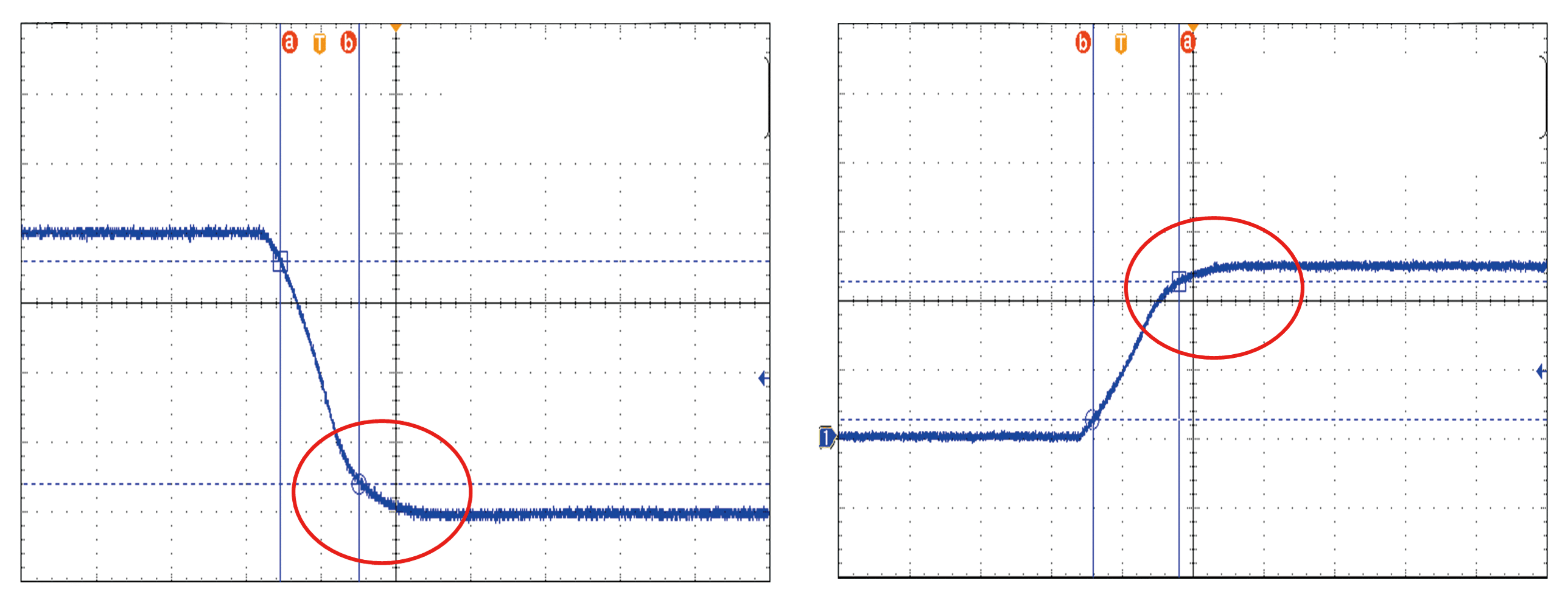

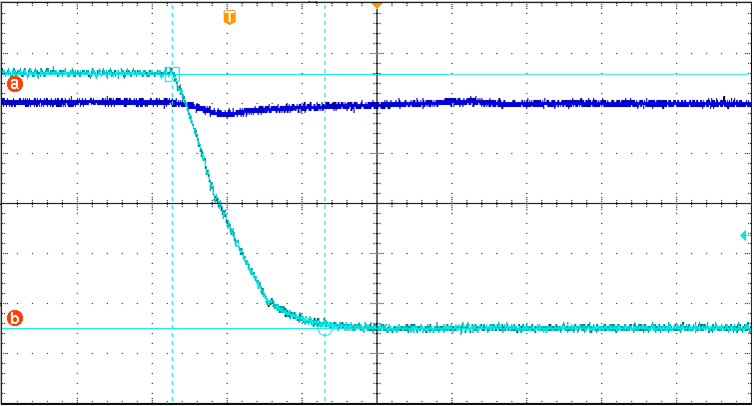

Quick Response Test Technology

Smooth current change between charge and discharge without overshoot to avoid damaging the battery.

- Current ripple noise <1%, Overshoot <1%

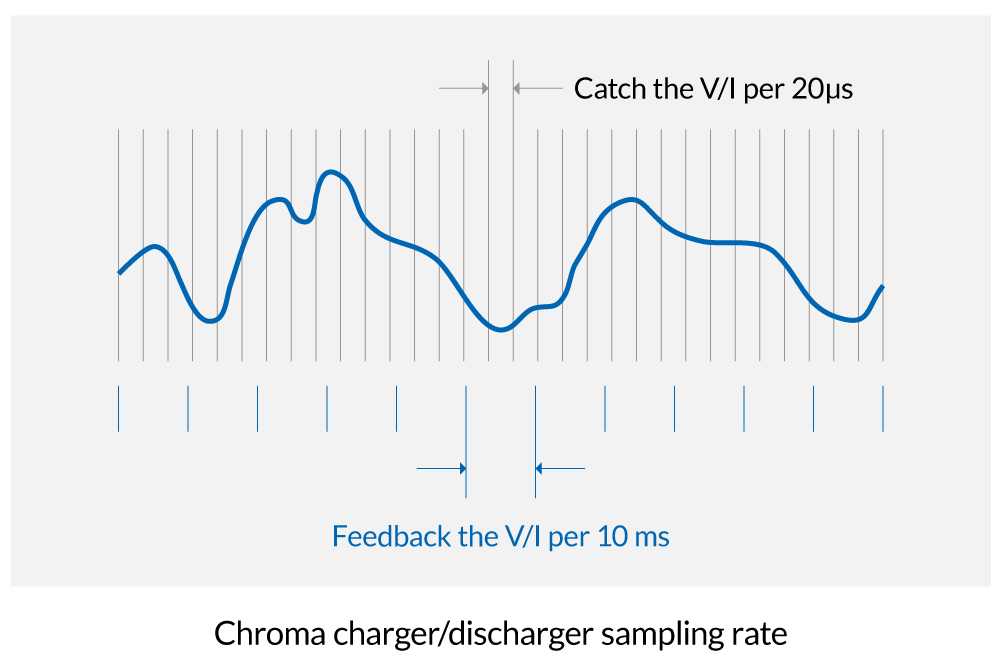

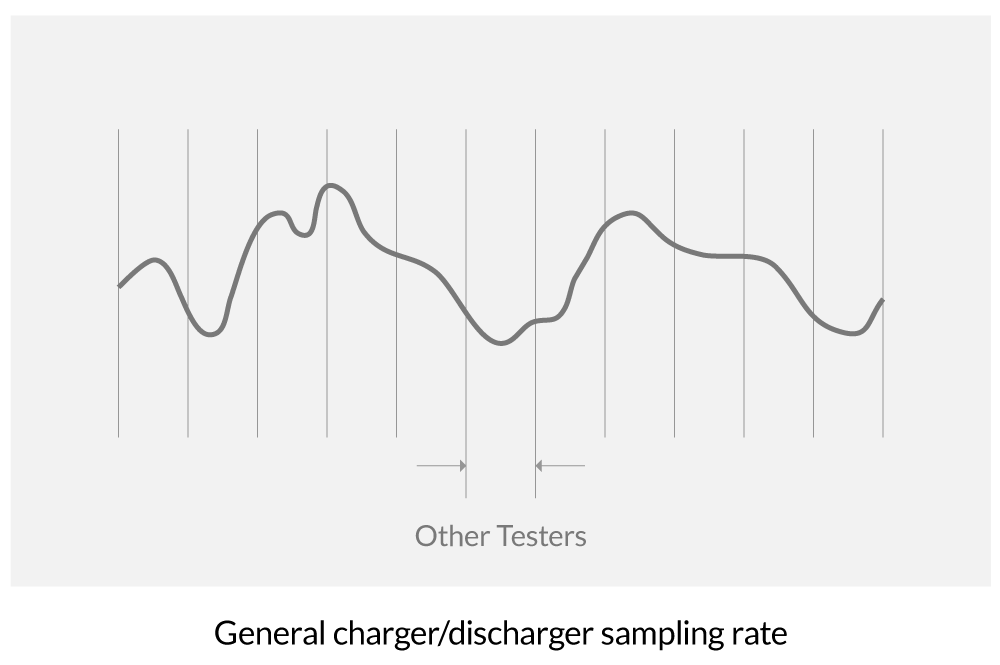

High Frequency Sampling Measurement Technology

Generally, battery chargers/dischargers use software to read current values for calculating power; however, limited data sampling rates could result in large errors when calculating the dynamic current capacity. By increasing the V/I sampling rate and using a double integration method, Chroma is able to provide a capacity calculation with much higher accuracy. When the current changes, the data is not lost and the transmission speed is not affected.

- V/I sampling rate: 50KHz (per 20μs)

- Integration calculus: I for capacity; V x I for energy

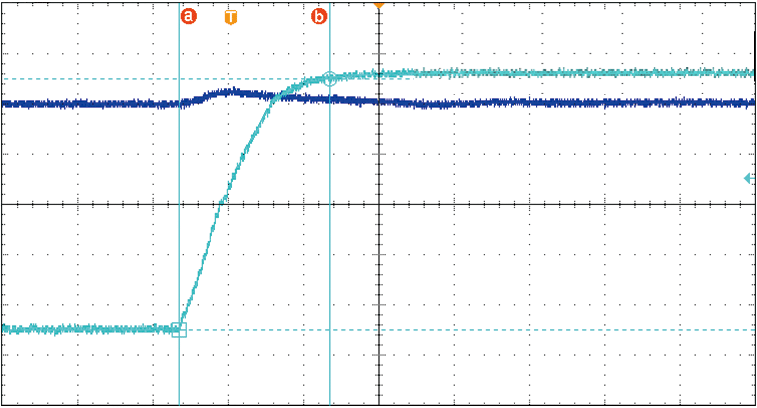

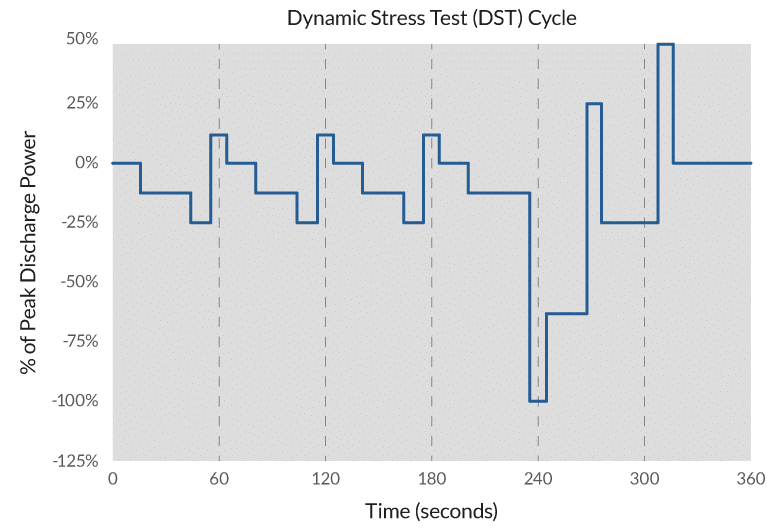

Dynamic Driving Profile Simulation

Battery packs are used under fast and irregular current conditions. The 17020E system simulates real conditions on the battery pack via the working condition simulator.

- Dynamic charge/discharge power or current waveforms simulate the drive cycle or any real world application. In the dynamic current mode (waveform), the current transition time from maximum discharge to maximum charge is only 10ms

- Ability to import stored current/power waveforms from an Excel file

- 720,000 points of driving profile memory are available to save the waveform profile in each channel

- Interval for profile condition changes: 10ms

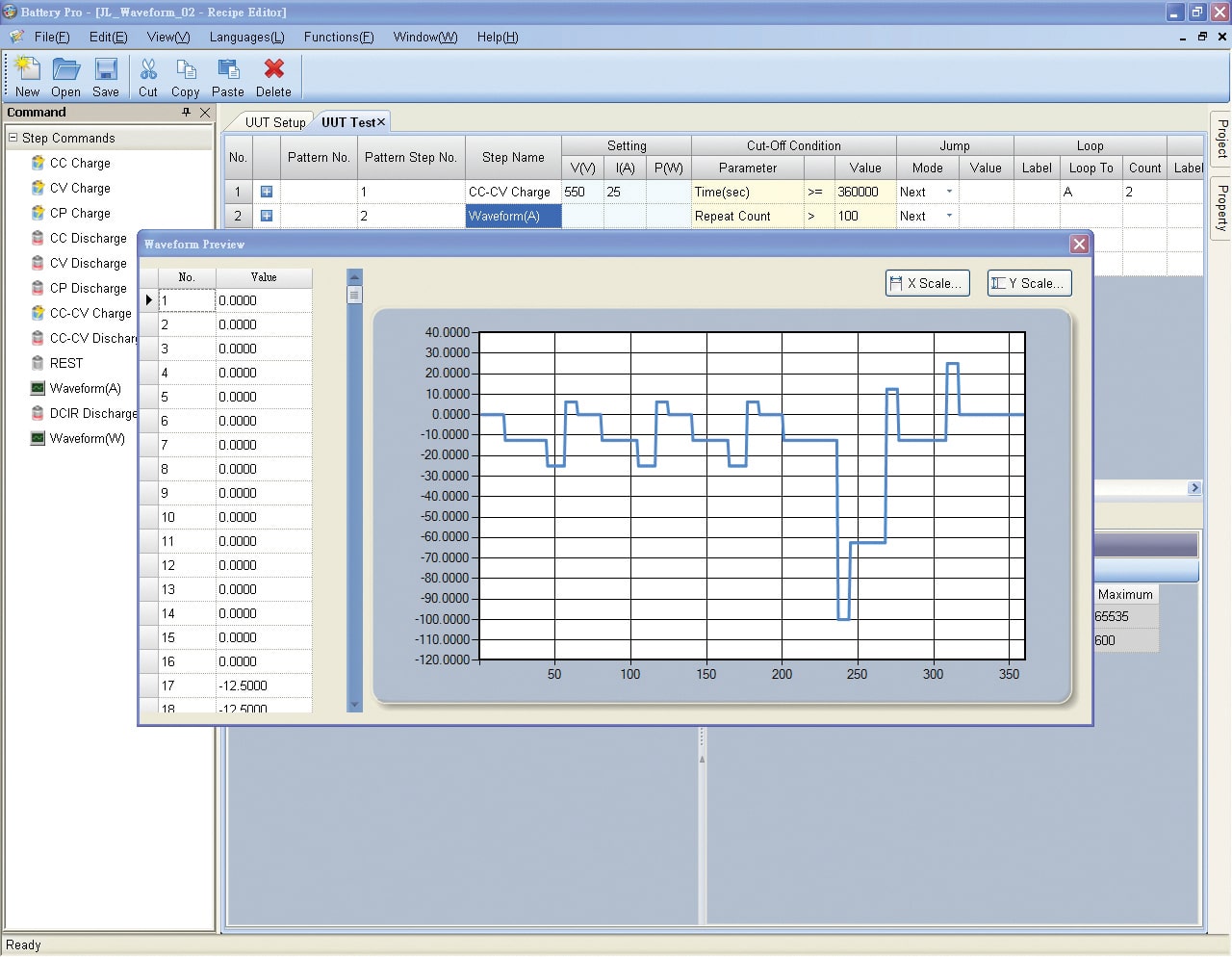

Recipe Editor

- 255 charge/discharge conditions

- Sets dual layer loops (cycle & loop) with 9999 loops per layer

- Ability to edit dynamic charge/discharge waveform with 10ms current switching speed

- Testing step: CV / CC / CP / CC-CV / Waveform current / DCIR)

- Cut-off conditions (time, current, capacity, cut-off voltage, cut-off current, etc.)

- Next Step: Next / End / Jump / Rest

Statistical Reports

- Customized report formatting and exporting of test reports to PDF, CSV and XLS

- Graphical report and analysis functions

- Report analysis function: allows creation of customized reports such as life-cycle reports, Q-V reports, V/I/T-time reports, etc., through the user-defined X and Y axis parameters

Software Integration

- Thermal chamber: Synchronizes temperature control with the charge/discharge profile

- Data logger: records temperature or voltage data that can be used for setting cut-off and protection conditions

- BMS data record: Software setting to read data from a BMS data communication unit (A692000/A692001) that supports RS485 and CAN bus. The data can be used for setting cut-off and protection conditions

Model Options

Model Options

| Model | Description |

| 17020E | Regenerative Battery Pack Test System 60V/180A/10kW/2CH/20kW |

| 17020E | Regenerative Battery Pack Test System 60V/180A/10kW/4CH/40kW |

| 17020E | Regenerative Battery Pack Test System 60V/180A/10kW/6CH/60kW |

| 17020E | Regenerative Battery Pack Test System 60V/180A/10kW/8CH/80kW |

| 17020E | Regenerative Battery Pack Test System 60V/360A/20kW/2CH/40kW |

| 17020E | Regenerative Battery Pack Test System 60V/360A/20kW/4CH/80kW |

| 17020E | Regenerative Battery Pack Test System 100V/100A/10kW/2CH/20kW |

| 17020E | Regenerative Battery Pack Test System 100V/100A/10kW/4CH/40kW |

| 17020E | Regenerative Battery Pack Test System 100V/100A/10kW/6CH/60kW |

| 17020E | Regenerative Battery Pack Test System 100V/100A/10kW/8CH/80kW |

| 17020E | Regenerative Battery Pack Test System 200V/100A/10kW/2CH/20kW |

| 17020E | Regenerative Battery Pack Test System 200V/100A/10kW/4CH/40kW |

| 17020E | Regenerative Battery Pack Test System 200V/100A/10kW/6CH/60kW |

| 17020E | Regenerative Battery Pack Test System 200V/100A/10kW/8CH/80kW |

| 17020E | Regenerative Battery Pack Test System 60V/100V/200V |

Accessories

| Model | Description |

| A170201 | IPC for battery test system |

| A692000 | BMS data communication unit, 4 Channels |

| A692001 | BMS data communication unit, 8 Channels |

| A692009 | Parallel block (60V/100V/200V) |

| A692010 | Parallel cable (500A) |

| A692011 | Parallel output fixture (60V/100V/200V) |

| A692012 | Parallel block on bottom side (60V/100V/200V) |

| A692003 | Thermal sensor with cable (for OTP) |

| HIOKI 8423/8948 | Data Logger Measurement Unit |

| HIOKI 9683 | Connection cable caption for HIOKI 8423 |

Battery Pro

Cell to Pack Level Charge-Discharge Testing with Real-time Monitoring

Battery Pro is an intuitive, multi-channel test software platform designed for cell to pack level charge-discharge testing with real-time monitoring. The software is item driven with built-in tests- meaning no programming is required at all.

Watch

17020 Regenerative Battery Pack Test System Overview

Accurate source and measurement ensure the test quality that is suitable for performing exact, reliable testing crucial for battery module / pack incoming or outgoing inspection as well as capacity, performance, production and qualification testing.