Exploring Hybrid Wound Component EST Scanner

Hybrid Wound Component EST Scanner

Chroma 19035

Powerful functions for Flashover detection and Open/Short Check (OSC) with programmable voltage and time parameters for various characteristics of DUTs

Mode (Model Specific)

AC / DC / IR / DCR -8CH

Channels

8 (up to 40 opt.)

Output Capability

AC: 0.05~5kV

DC: 0.05~6kV

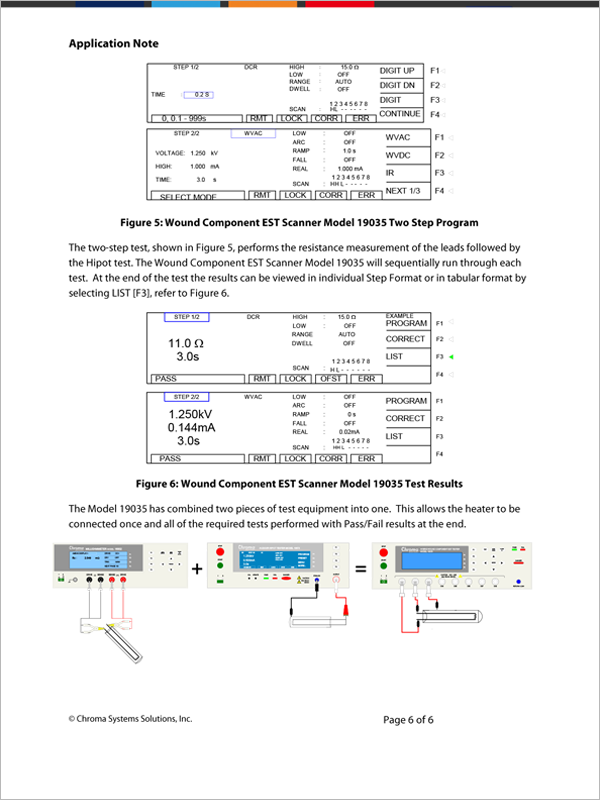

The quality verification test items for Wound Components consist of AC/DC Hipot tests and Insulation Resistance (IR) tests. Chroma integrates the above tests into the Hybrid 19035 Wound Component EST Scanner series to perform safety tests for motor, transformer, and heater related wound products. The wound component manufacturers performing quality verification testing will not only have reliable quality, but also can control product quality efficiently.

Flashover Detection

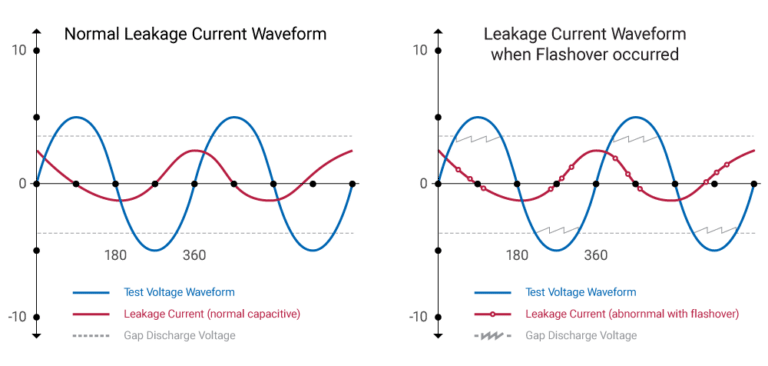

Chroma 19035 has the same Flashover detection as other Chroma EST testers. Flashover is the electrical discharge generated by high electrical fields inside or on the surface of insulation materials that cause the DUT to lose its insulation characteristics and form a transient or discontinuous discharge. It can cause a carbonized conductive path, or damage the product under test. Flashover cannot be detected by monitoring leakage current only. The change rates of test voltage and leakage current must be monitored in order to detect flashover, as its detection is one of the most indispensable test items for electrical safety testing.

Ground Fault Interrupt (GFI)

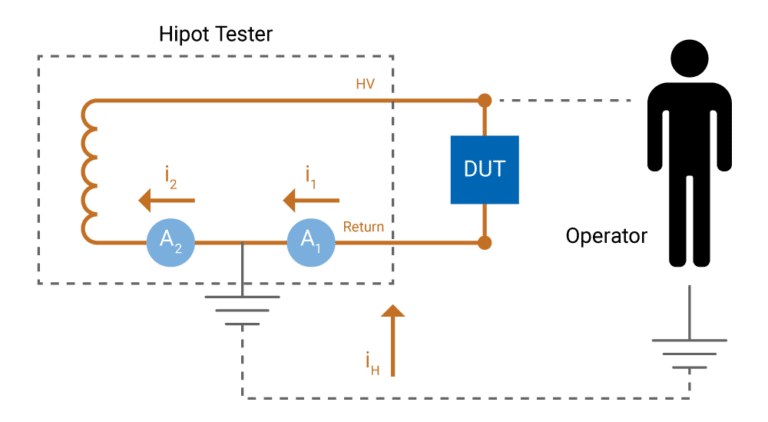

The requirements for test environments indicates that test equipment is to be equipped with an auto interrupt device, so Chroma built in a Ground Fault Interrupt (GFI) function. When the current meter A1 and A2 detect a difference (i2-i1 = iH ) between the value i1 and actual i2 test current over high, this device can cut the power transiently for protecting against electrical shock to the operator. It is not only according to safety standards but also provides additional safeguards for test personnel.

More Features

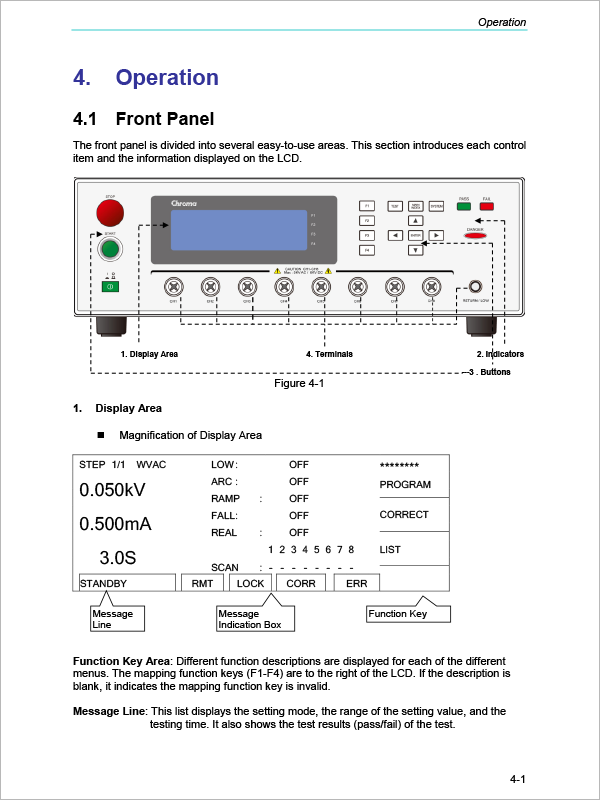

Programmable Voltage

and Time Parameters

Friendly Interface

Key Lock

Function

Optional GPIB &

Handler Interface

The 19035 Series is a comprehensive safety tester designed for motor, transformer, and heat related wound component tests. Most wound components have multiple windings, such as 3-phase motors and dual winding transformers. With 8-channel scanning ability the 19035 can measure multiple test points in one test instead of switching test points manually. This reduces test time and labor cost immensely.

Model Options

| Model | Description |

| Hybrid 19035 | Wound Component EST Scanner |

| Accessories | |

| A190343 | 19″ Rack Mount Kit |

| A190347 | GPIB/Handler/Temp Interface |

| A190348 | RS232 Interface #2 |

| A190351 | 8CH-16CH Scan Box |

| A190359 | 16CH HV Scan Box |

| A190358 | Handler Indicator |

| A190512 | Auto Control TR. Scan Box |

Watch

Webinar: Electrical Safety Testing 101

Get an overview of the basic principles of electrical safety testing.