As AI technology continues to advance rapidly, the training and inference of AI models requires increasingly large-scale, uninterrupted, high-efficiency computing. This places greater demands on the stability and performance of power delivery systems. To meet these demands, the Sidecar power architecture was developed—separating the power system from the server motherboard and introducing a modular, pluggable design. Central to this concept is a high-voltage direct current (HVDC) system that uses ±400V DC as the main transmission backbone. This approach reduces line losses, improves energy transmission efficiency, and frees up rack space to enable higher-density deployments and flexible power management.

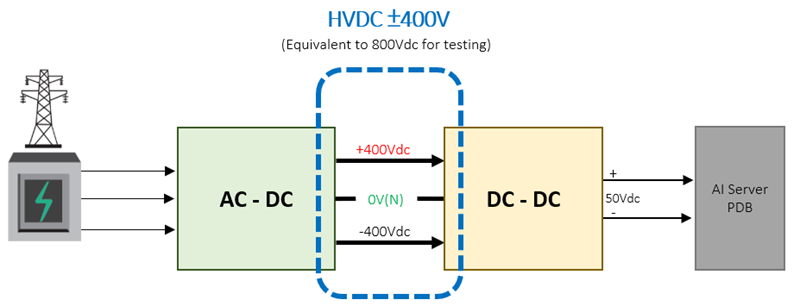

The Sidecar architecture consists of two main modules (AC-DC and DC-DC) with ±400V HVDC serving as the critical link between them:

- AC-DC Module: Converts AC input to ±400V DC, serving as the main output voltage of the HVDC system.

- DC-DC Module: Steps down the ±400V HVDC to DC levels required by the AI server’s computing components.

Testing requirements for these modules span individual PSUs, power shelves, and complete power rack systems, with power ratings ranging from 25kW to 800kW and even higher. The AC-DC module requires an HVDC electronic load, while the DC-DC module must be paired with an HVDC power source. Since ±400V represents an 800V differential, the test solution must offer high flexibility and support parallel configuration to accommodate varying power levels. Ideally, the test equipment should also have bidirectional capability, functioning as both a power source and an electronic load to meet the diverse testing needs of different modules.

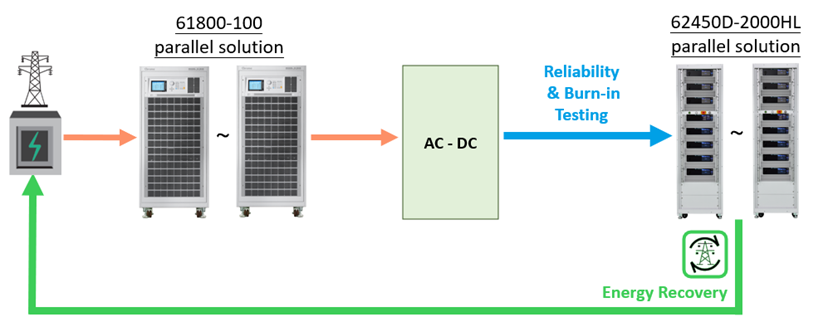

Chroma’s 62450D-2000HL Bidirectional DC Power Supply is designed with high power density, delivering up to 45kW output in a compact 4U chassis. With master-slave parallel configuration, it can deliver up to 360kW in a standard 41U 19-inch rack, and scale even further to MW-level output through cross-cabinet parallel connection. This allows full coverage of Sidecar-based power module requirements, providing flexible configurations for PSU, power shelf, or power rack testing at any power level.

For long-duration use cases such as reliability testing and burn-in of Sidecar HVDC AC-DC modules, the 62450D-2000HL features a built-in regenerative load function that recycles test energy back to the grid. At rated operation, it achieves up to 94% energy recovery efficiency, helping reduce electricity costs, lower carbon emissions, and ease the burden on cooling systems.

For DC-DC module testing, the 62450D-2000HL also serves as a stable and reliable HVDC source. With a built-in dual voltage range (High/Low), it supports 400V or 800V input configurations based on testing needs, allowing flexible current scaling and equipment setup for consistent power delivery.

As the AI server market advances toward higher efficiency, greater flexibility, and HVDC-based power architectures with increased power demands, Chroma’s 62450D-2000HL stands out with its dual-mode capabilities as both power supply and regenerative load. Its high-efficiency energy recovery and versatile application modes make it a powerful enabler for AI innovation as well as sustainable energy goals.