Exploring High Power DC Electronic Loads

High Power DC Electronic Loads

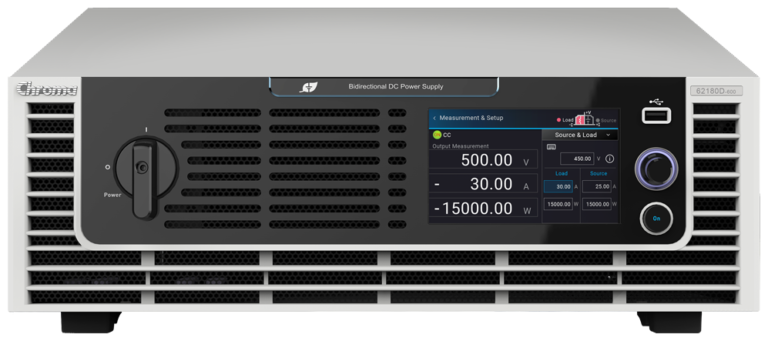

Chroma 63200A

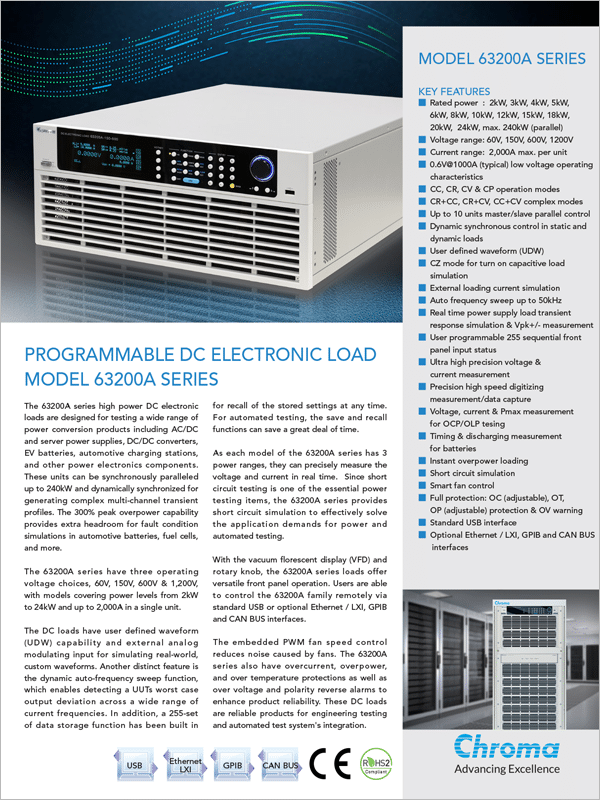

High power DC electronic loads designed for testing AC/DC power supplies, batteries and energy storage systems, EV/EVSE, and other power electronics.

Power Rating

2kW~24kW, up to 240kW

Voltage Range

0~20V / 0~150V / 0~600V / 0~1200V

Current Range

up to 2000A

Chroma High Power DC Electronic Loads provide wider operating voltage and current ranges up to 240kW, sine wave loading, dynamic frequency sweep to 50kHz, digitizing, MPPT, an impressive front panel that tilts, and the highest accuracy available (voltage 0.015% + 0.015% F.S. and current 0.04% + 0.04% F.S.) – all with an incredibly high power density (6kW @4U).

Not found in conventional loads, the 63200A offers a dynamic frequency sweep with variable frequencies up to 50kHz. This capability is ideal for determining worst case voltage peaks. Using this function, measurement of the Vpeak (+/-) can be achieved with a sampling rate of 500kHz. The dynamic loading mode can simulate different loading conditions for most test requirements. Dedicated remote load sensors and control circuits provide minimum waveform distortion during dynamic loading.

Ultra High Power Density & User-Defined Hot Key Design

Ultra high power density design eliminates other large and cumbersome high power loads. With its small footprint, it solves space issues when upgrading electronic loads in automated test systems. In addition, the 63200A provides 4 sets of user defined hot keys that enable the user to enter operation modes quickly.

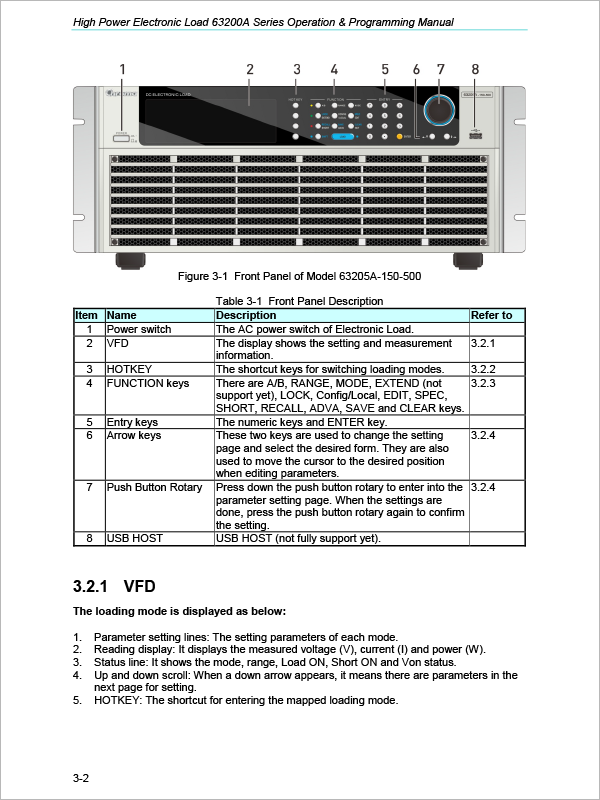

Iconic Function Selections

Iconic function selections make it easier for users to control and operate the 63200A series. Basic and advanced functions are iconized, so that users can select from the functions either from the rotary knob or using arrow keys. The abbreviations are displayed in the icons, and full descriptions are displayed on the VFD display to allow users to easily operate the load without referring to an operation manual for every step.

Simulate Loading Characteristics of AI Microprocessors

The 63202A-20-2000 Ultra-Low Voltage DC Electronic Load is designed for applications of 2,000A@0.2V and 1,000A@0.1V, such as simulating loading characteristics of AI microprocessors and engineered for reliable testing of VRMs, VRDs, POLs, and D2Ds. It is also well-suited for EVs, fuel cells, and other low voltage-high current applications. The instrument features a unique front copper busbar design that provides low inductance connections, enabling industry-leading slew rates and minimizing IR voltage drops due to cable resistance.

More Features

Synchronize with

Multiple Loads

Master/Slave

Parallel Control

Programmable

Slew Rate

Timing & Discharging Measurement

for Batteries

In addition to standard CC, CV, CP, and CR loading modes of conventional loads, the 63200A accepts digital data from DAQ cards or analog data from function generators to allow for complex waveforms. The 63200A also provides an enhanced User Defined Waveform (UDW) feature to simulate the current profiles and waveforms. To create the current waveform, the user can upload captured waveform data into any load via Chroma’s softpanel. Each load can store up to 10 sets of waveforms, each comprising up to 1.5 million data points, to meet the more strenuous test requirements. In addition, the 63200A series also provides voltage peak measurement during actual loading conditions, avoiding the need for an oscilloscope to capture the voltage peak.

Model Options (2kW-24kW)

| Model | Height | Description |

| 63202A-20-2000 | 3U | Ultra-Low Voltage DC Electronic Load 20V / 2000A/ 2kW |

| 63203A-150-300 | 3U | Programmable High Power DC Electronic Load 150V / 300A/ 3kW |

| 63203A-600-210 | 3U | Programmable High Power DC Electronic Load 600V / 210A / 3kW |

| 63203A-1200-120 | 3U | Programmable High Power DC Electronic Load 1200V / 120A / 3kW |

| 63204A-150-400 | 4U | Programmable High Power DC Electronic Load 150V / 400A/ 4kW |

| 63205A-150-500 | 4U | Programmable High Power DC Electronic Load 150V / 500A / 5kW |

| 63206A-150-600 | 4U | Programmable High Power DC Electronic Load 150V / 600A / 6kW |

| 63204A-600-280 | 4U | Programmable High Power DC Electronic Load 600V / 280A / 4kW |

| 63205A-600-350 | 4U | Programmable High Power DC Electronic Load 600V / 350A /5kW |

| 63206A-600-420 | 4U | Programmable High Power DC Electronic Load 600V / 420A /6kW |

| 63204A-1200-160 | 4U | Programmable High Power DC Electronic Load 1200V / 160A / 4kW |

| 63205A-1200-200 | 4U | Programmable High Power DC Electronic Load 1200V / 200A / 5kW |

| 63206A-1200-240 | 4U | Programmable High Power DC Electronic Load 1200V / 240A / 6kW |

| 63206A-60-1000 | 4U | Programmable High Power DC Electronic Load 60V / 1000A / 6kW |

| 63208A-150-800 | 7U | Programmable High Power DC Electronic Load 150V / 800A/ 8kW |

| 63210A-150-1000 | 7U | Programmable High Power DC Electronic Load 150V / 1000A/ 10kW |

| 63212A-150-1200 | 7U | Programmable High Power DC Electronic Load 150V / 1200A/ 12kW |

| 63208A-600-560 | 7U | Programmable High Power DC Electronic Load 600V / 560A/ 8kW |

| 63210A-600-700 | 7U | Programmable High Power DC Electronic Load 600V / 700A/ 10kW |

| 63212A-600-840 | 7U | Programmable High Power DC Electronic Load 600V / 840A/ 12kW |

| 63208A-1200-320 | 7U | Programmable High Power DC Electronic Load 1200V / 320A/ 8kW |

| 63210A-1200-400 | 7U | Programmable High Power DC Electronic Load 1200V / 400A/ 10kW |

| 63212A-1200-480 | 7U | Programmable High Power DC Electronic Load 1200V / 480A/ 12kW |

| 63215A-150-1500 | 10U | Programmable High Power DC Electronic Load 150V / 1500A/ 15kW |

| 63218A-150-1800 | 10U | Programmable High Power DC Electronic Load 150V / 1800A/ 18kW |

| 63215A-600-1050 | 10U | Programmable High Power DC Electronic Load 600V / 1050A/ 15kW |

| 63218A-600-1260 | 10U | Programmable High Power DC Electronic Load 600V / 1260A/ 18kW |

| 63215A-1200-600 | 10U | Programmable High Power DC Electronic Load 1200V / 600A/ 15kW |

| 63218A-1200-720 | 10U | Programmable High Power DC Electronic Load 1200V / 720A/ 18kW |

| 63220A-150-2000 | 13U | Programmable High Power DC Electronic Load 150V / 2000A/ 20kW |

| 63220A-600-1400 | 13U | Programmable High Power DC Electronic Load 600V / 1400A/ 20kW |

| 63220A-1200-800 | 13U | Programmable High Power DC Electronic Load 1200V / 800A/ 20kW |

| 63224A-150-2000 | 13U | Programmable High Power DC Electronic Load 150V / 2000A/ 24kW |

| 63224A-600-1680 | 13U | Programmable High Power DC Electronic Load 600V / 1680A/ 24kW |

| 63224A-1200-960 | 13U | Programmable High Power DC Electronic Load 1200V / 960A/ 24kW |

| Accessories | ||

| A632007 | Over Voltage Protection Box 1200V/50A [for 63200A-1200V models] | |

| A632009 | DC Load Slave Unit 600V / 1680A / 24kW | |

| A632010 | DC Load Slave Unit 1200V / 960A / 24kW | |

| A600009 | GPIB cable (200cm) | |

| A600010 | GPIB cable (60cm) | |

| A636000 | GPIB interface | |

| A636010 | Ethernet interface | |

| A632006 | NI USB-6211 Bus-Powered Multifunction DAQ | |

| 11460 | SoftPanel KIT – Includes Software and Dongle Key | |

| L11 000906 | 19″ Rack Mounting Kit for model 2kW & 3kW 63200A (3U) | |

| 11565 | 19″ Rack Mounting Kit for model 4kW, 5kW & 6kW 63200A (4U) | |

Model Options (48kW-240kW High Power)

| Model | Description | Specifications | |

| 63200A-48-150 | 48kW DC Electronic Load | 48kW / 150V / 4000A | |

| 63200A-48-600 | 48kW DC Electronic Load | 48kW / 600V / 3360A | |

| 63200A-48-1200 | 48kW DC Electronic Load | 48kW / 1200V / 1920A | |

| 63200A-60-150 | 60kW DC Electronic Load | 60kW / 150V / 5200A | |

| 63200A-60-600 | 60kW DC Electronic Load | 60kW / 600V / 4200A | |

| 63200A-60-1200 | 60kW DC Electronic Load | 60kW / 1200V / 2400A | |

| 63200A-120-150 | 120kW DC Electronic Load | 120kW / 150V / 10000A |  |

| 63200A-120-600 | 120kW DC Electronic Load | 120kW / 600V / 8400A | |

| 63200A-120-1200 | 120kW DC Electronic Load | 120kW / 1200V / 4800A | |

| 63200A-240-150 | 240kW DC Electronic Load | 240kW / 150V / 20000A |  |

| 63200A-240-600 | 240kW DC Electronic Load | 240kW / 600V / 16800A | |

| 63200A-240-1200 | 240kW DC Electronic Load | 240kW / 1200V / 9600A | |

Watch

Webinar: Chroma E Load

This seminar highlights key features and functions of our DC electronic loads and the many applications they are being used for all over the world.

Related Products

Modular DC Electronic Load LED Simulator

Chroma 6310/A

200W/30W & 250W/300W/600W/1200W

0~500V

0~20A

Simulate LED characteristics with increased bandwidth to allow for PWM dimming testing; Ideal for the test and evaluation of multi-output AC/DC power supplies, DC/ DC converters, chargers and power electronic components