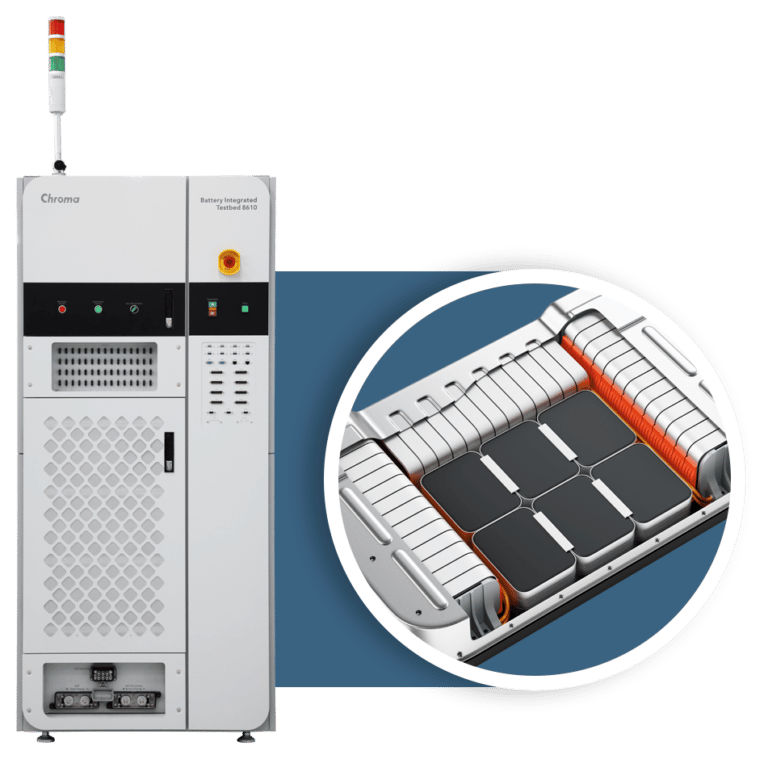

Exploring Regenerative Battery Pack Test System

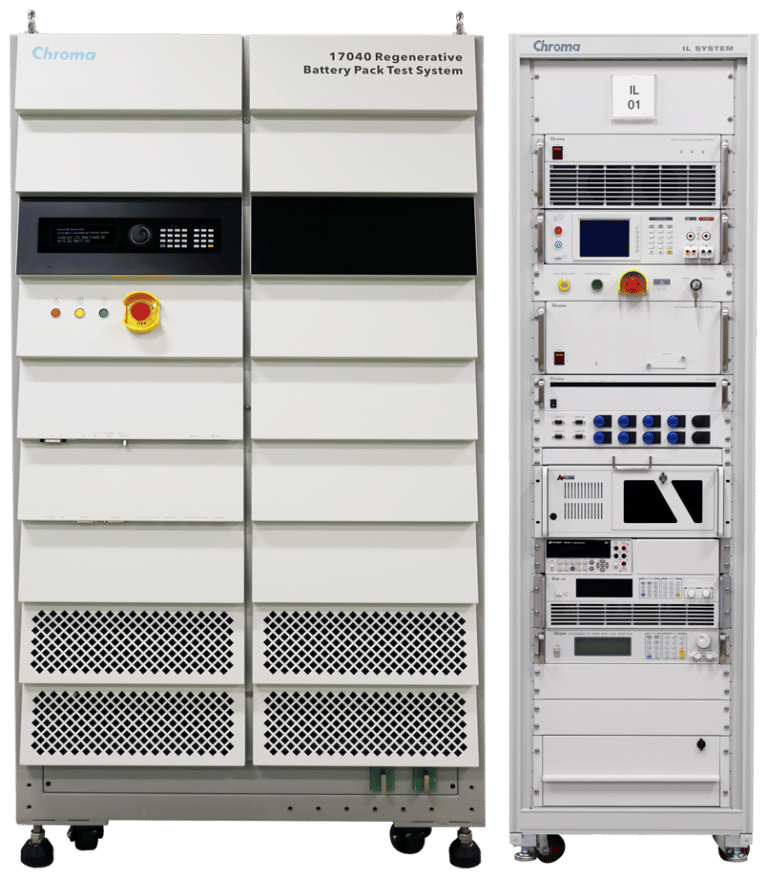

Regenerative Battery Pack Test System

Chroma 17020C

High-precision system designed for repeated and reliable testing of secondary battery modules and packs; ideal for incoming and outgoing inspections as well as capacity, performance, production, and qualification testing

Power Range

10KW-80kW per channel with addition of 10kW per module

Voltage Range

150V

Current Range

100A per channel and parallel up to 800A

Battery Test System with Independent Channels and Flexible Programming

Chroma 17020C Battery Tester is a high-precision, regenerative system designed for repeated and reliable testing of secondary battery modules and packs. Offering highly accurate sourcing and measurement, the 17020C is ideal for incoming and outgoing inspections as well as capacity, performance, production, and qualification testing.

Regenerative Battery Discharge Capabilities

The test system efficiently recycles the energy discharged from a battery module, either from one channel to other charging channels or back to the grid, saving power and reducing thermal footprint.

Multiple Independent Channels

Supports dedicated charge/discharge tests on multiple battery modules or packs with distinct test characteristics. Channels can be paralleled for higher current requirements, offering flexibility between high channel count and high-current test.

Flexible Programming Functions

Operated with Chroma’s user-friendly Battery Pro X software, which allows easy creation and execution of tests without needing advanced programming skills. Features include graphically aided test creation, pre-defined profiles, real-time monitoring, and integration with external equipment.

Rapid Slew Rate

The 17020C features a -90% to +90% slew rate of 10ms, allowing it to replicate real drive profile conditions for accurate simulation of dynamic driving scenarios.

Safety Features

Includes Battery Polarity Check, Over Voltage Protection, Over Current Protection Check, Over Temperature Protection, and VDE-4105-AE Islanding Detection. Tested data is securely stored in non-volatile memory to prevent data loss during power or communication failures. With flexible programming functionality and user-friendly operating software, the Chroma 17020C provides a convenient, robust, and efficient solution for comprehensive battery test.

Key Features

- Battery charge/discharge modes (CC, CV, CP)

- Power Range: 10KW-80kW per channel with addition of 10kW per module

- Voltage Range: 150V

- Current Range: 100A per channel and parallel up to 800A

- Regenerative battery energy discharge with >90% efficiency

- Energy and Cost saving

- Low heat and less noise generation

- D/D efficiency: 95-97% (>5% rated power)

- Standby loss 2.56W per channel

- Parallel channel control through software

- Driving cycle simulation with 5ms slew rate from 10% to 90%.

- High resolution measurement (18bit)

- Smooth current transition from charge to discharge or vice versa without over shoot

- Graphically aided test data analysis and statistics

- Data recovery protection after power failure

Applications

- EV battery module

- Electric scooter

- Electric bike

- UPS

- Energy storage battery

- Power tools

- Car battery

- Lead-acid battery

System Functions

Full current discharge

Full current discharge at 3V. Discharge current decreases below 3V as follows: 2V/-85A, 1.5V/-65A, 0.3V/-16A

Two measurement ranges and improved accuracy

- Voltage ranges: 60V/150V;

- Current range: 50A/100A

- Voltage accuracy: 0.02%FS, 60V ±12mV/150V ±30mV

- Current accuracy: 0.05%FS, 50A±25mA/100A±50mA

Smooth current transition from discharge to charge cycle

- Stable current, no overshoot during the transition

- No current interruption when switching from charge to discharge

Operating modes

- Constant Current (CC)

- Constant Voltage (CV)

- Constant Power (CP)

- Constant Resistance (CR)

- Constant Voltage-Limit

- Current (CC-CV)

- Constant Power-limit Current (CP-CC)

- Rest mode

- Waveform current mode

- DCIR mode

- CV source mode

Regenerative battery energy discharge

- Recycled back to grid or internal loading

- Low heat output, reducing

- HVAC power consumption

- THD less than 5% at rated power

- PF over 0.9 at rated power

Communication between tester and controller

- Fast and efficient data handling: data is processed without buffering, ensuring low-latency communication across the network

- Ensures timely and accurate data exchange between devices in the daisy chain

- Min sampling rate 10ms

Protection conditions

- OVP, UVP, OCP, UCP, OTP, UTP, over/under capacity (Ah) protections

- Reverse connection, Wire loss protection (ΔV)

- Delta Protection: -ΔV/+ΔV (V), +ΔI/-ΔI (A) protections

Report data recording parameters

- STEP

- Test TIME

- Real TIME ID

- Cycle

- Loop

- STEP MODE

- STEP TIME

- VOLTAGE(V)

- CURRENT(A)

- CAPACITY (Ah)

- Energy(Wh)

- CUT OFF VOLTAGE(V)

- CUT OFF CURRENT(A)

- CUT OFF CAPACITY(Ah)

- DCIR(mOhm)

- TEMPERATURE(˚C)

Fast current response for dynamic drive curve simulation

- Minimum slew rate of 5ms(10% to 90%)

- Report recording interval of 10ms

- Dynamic charge/discharge power and current waveforms comply with NEDC, FUDS and HPPC standards

System Configuration

- Multi-function frame with BMS communication ports

- AC-DC bidirectional converter

- Regenerative charge/discharge tester model 69210C series

- Industrial PC (option)

- Tower light for status indicator

- Rack arm monitor with keyboard stand

- Datalogger placement (option)

* Supports other equipment upon request

Graphic User Interface - Battery Pro X

The 17020C test system is engineered to meet the diverse requirements of testing secondary battery packs at a high level of safety and stability. The system’s charge and discharge protection mechanisms automatically halt testing when abnormal conditions are detected, while its robust data storage and recovery features provide safeguards against data loss due to power failure.

Recipe Editor

- Two-layered recipe list

- 500 charge/discharge conditions

- Set dual-layer loops (cycle & loop) with 999999 loops per layer

- Edit dynamic charge/discharge waveforms with 10ms current switching speed

- Testing steps: CV/CC/CP/CC-CV/Waveform current/DCIR

- Cut-off conditions (time, current, capacity, cut-off voltage, cut-off current, etc.)

- Next Step options: Next/End/Jump/Rest

Statistical Reports

- Detailed report and step report generation

- Customized report format, exports test reports in PDF, CSV and XLS

- Graphical report function

- Report analysis function: create customized reports such as life-cycle report, Q (AH)-V (V) report, and V(V)/I(A)/T (ºC)-time report through user-defined X and Y axis parameters

- Real-time browsing of per-channel test reports

Watch

Webinar: EV Power Components, A Total Testing Solution from the EVSE to the Battery

This seminar has been put together to demonstrate the improvements made to EV testing performance with newly developed instruments, functional test systems, battery test and simulation systems. Get an overview of the entire scope of work with reliable, precision instrumentation and systems including electrical safety testing for multiple applications.

Related Products

Regenerative Battery Pack Test System

Chroma 17020C

10KW-80kW per channel with addition of 10kW per module

150V

100A per channel and parallel up to 800A

High-precision system designed for repeated and reliable testing of secondary battery modules and packs; ideal for incoming and outgoing inspections as well as capacity, performance, production, and qualification testing

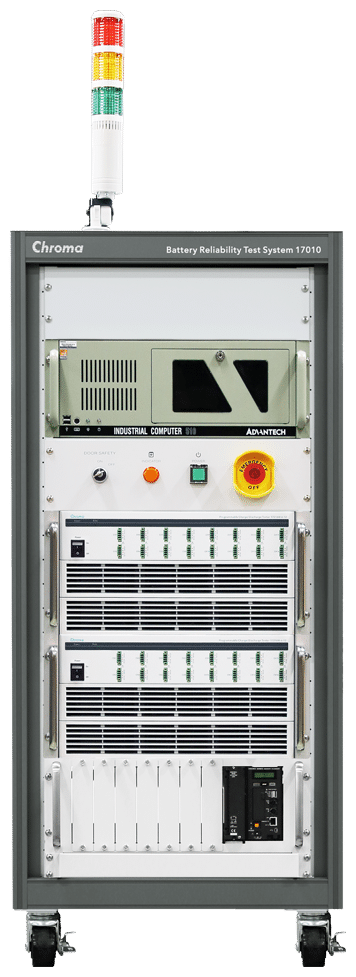

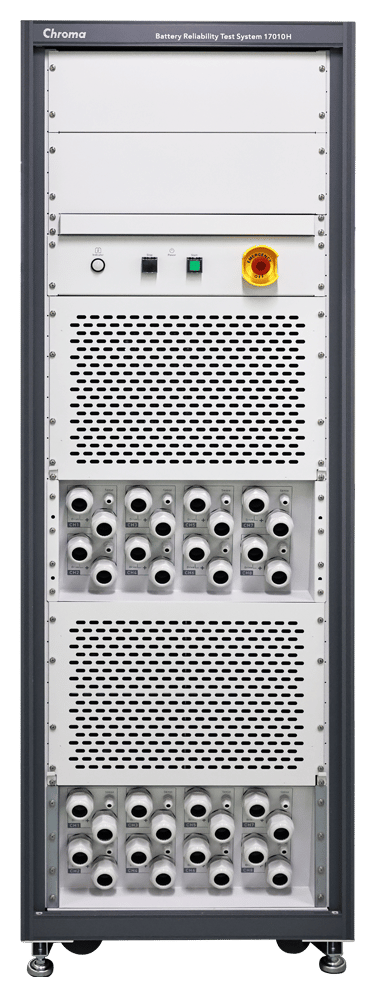

Battery Reliability Test System

Chroma 17010

Up to ±0.015% of full scale

Up to 100µS

Up to 10mS

Chroma’s Battery & Reliability Test System is a high-precision system designed specifically for testing lithium-ion battery (LIB) cells, electric double-layer capacitors (EDLCs), and lithium-ion capacitors (LICs).

Battery Pack ATS

Chroma 8720

5kW ~ 350kW

0V~900V

0A~1000A

Test the battery packs in end of line (EOL) production for a comprehensive Pass/Fail check, including mechanism assembly, pressure insulation, BMS communication, internal high voltage relay parts, battery balance, and temperature distribution, etc.