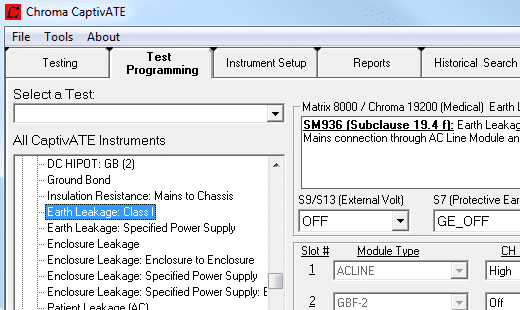

CaptivATE provides an Off-The-Shelf Electrical Safety Test Solution for accurately performing automated hipot, leakage current and functional tests.

Testing is made simple and fast by automatically downloading the test setup, conducting the required measurements and outputting the test results. CaptivATE automates the process of electrical safety testing when used with Chroma’s Guardian 19050 Series Hipot Testers, Guardian 19032 Series Electrical Safety Analyzer, Hybrid 19035 Wound Component EST Scanners, Sentinel series ATS, and the Chroma 11025 and QuadTech 1730T LCR Meters.

Key Features

- Self Executable Install

- Local or Shared Network Database

- Four Levels of Accessibility – Password Verification

- Intuitive Interface: Virtual Front Panel and Windows

- Virtually Unlimited Number of Tests – Up to 990 Steps Each

- Local or Remote Printing

- Test Device Setup with Serial Number Logging

- Automatically Load Tests at Beginning of Each Test

- Automatically Verify Test Program at Beginning of Each Test

- Historical Database Search

- Archived Test Report Search

- Separate Options for Saving and Printing Pass & Fail Reports

- Standard & Summary Reports in MS Word or in XML and CSV Formats

- Batch Testing & Reports

- Create Aliases for Generic Modes

- Engineering Notation

- Text Fields for Operator Comments on Test Failures, Functional Check, and Virtual Pause

- Numeric Functional Check

- Document Retrieval

Uses

- Automated Production Testing

- Automated Assembly Line

- Quality Assurance Testing & Statistical Process Control

- Research or Laboratory Analysis

- Historical Database Archiving

- Additional Features

- version 4.1.0 Updates

- specifications

Testing Capability

Using the CaptivATE software and a Guardian 19032 Series Safety Analyzer, possible test functions include: AC or DC Hipot, insulation resistance, ground bond, earth leakage, patient leakage, patient auxiliary leakage or enclosure current leakage, as well as a functional check. Provides tests for ISO 60601/60950/61010/60335 requirements.

Automatic Loading Test Setup:

The test setup can be loaded and verified by using a bar code scanner to identify both the product model and serial number(s). This reduces the possibility of an operator selecting the incorrect test for the product.

Increased Productivity

All the electrical safety and functional testing can be combined into one test system, thus eliminating the need for multiple setups and test stations. The intuitive graphic interface is easy and efficient for the test operator, reducing operator error.

Plant-Wide Implementation

Multiple installations of CaptivATE (plantwide or globally) can share the same database, providing a central data location that is updated in real-time. A single installation license is required for each test system.

Paperless Testing

Saves and prints all measurement results as well as product model number, serial number, time and date, test operator, test instrument used and test name. Prints and electronically stores product test certificates.

Password Protection

CaptivATE provides four levels of accessibility (Operator, Technician, Engineer and Administrator), providing control of specific functions within the testing process.

- New Chroma instruments support

- Microsoft Office 2007, 2010 and 2013 support

- Microsoft Windows 7, 8, and 10 (32-bit & 64-bit) full compatibility

Supported Operating System:

- Microsoft Windows 7, 8, 10 (32-bit and 64-bit), and XP

Supported Microsoft Office versions:

- 2007, 2010, or 2013

Minimum PC Hardware Requirements:

Windows XP:

- 800MHz Pentium (or compatible) Processor

- 128MB RAM

Windows 7:

- 1GHz or faster 32-bit or 64-bit Processor

- 1GB (32-bit) or 2GB (64-bit) RAM

Windows XP and 7

- 800MB Hard Disk Space (Includes hard disk space required for program files only, Additional hard disk space required for database)

- CD-ROM or DVD Drive

- Microsoft Windows compatible keyboard

- Microsoft Windows compatible mouse or pointing device

- Microsoft Windows compatible printer

- Super VGA Monitor with 800×600 Resolution or higher

- 1 x RS232 Port *

- 4 x USB or USB 2.0 Ports for instrument connection

Optional Requirements:

- Microsoft Windows compatible network

- Windows compatible printer capable of 8.5″x11″ or 2″x3″ media

- Microsoft Access 98 or greater

Optional Equipment:

- Barcode Scanner

Instruments Supported: 11025 / 1730T

- Firmware 2.0 (or higher)

- IEEE488 installed

- Guardian 19032 / 6000 Plus

- Firmware 5.13 (or higher)

- Scanners: (4 Total)

- 1 INT Scanner: 6000-01/A190302, -02/A190303 or -03/A190304 (Optional)

- 3 EXT Scanner: 5000-01, -02, -03 or -04 (Optional)

- G45 40A GB Transformer (Optional)

Guardian 19020 Multi-Channel Hipot Tester

- Up to 10 channels

- Only Master unit supported, no support for Slave units

Guardian 19020-4 Multi-Channel Hipot Tester

- Up to 4 channels

- Only Master unit supported, no support for Slave units

Guardian 19032 and 19032-P with A190308 / 6100 Plus

- Firmware 5.13 (or higher)

- Scanners: (5 Total)

- 1 INT Scanner: 6000-07/A190308 (Standard)

- 4 EXT Scanners: 5000-01, -02, -03 or -04 (Optional)

- G45 40A GB Transformer (Optional)

- Guardian 19055 / 500 VA Plus

- Firmware 2.0 or higher

- RS232 installed

Guardian 19036 Wound Component EST Analyzer

- 5 Basic tests are supported:

- AC Hipot

- DC Hipot

- Insulation Resistance

- DCR 4 Wire

- Open/Short Check

- The HSCC (High Speed Contact Check), IWT (surge), △/Y DCR, ITW Compare, Inductance Mode (Lx), Lx Balance, temperature compensation and Sub steps test modes and features are NOT supported.

AC Sources:

- 6408-1: 800VA AC Source – FW 2.2 (or higher)

- 61601 / 31005: 500VA AC Source – FW 1.05 (or higher)

- 61602 / 31010: 1000VA AC Source – FW 1.05 (or higher)

- 61603 / 31015: 1500VA AC Source – FW 1.1 (or higher)

- 61604 / 31020: 2000VA AC Source – FW 1.2 (or higher)

- 61605 / 31040: 4000VA AC Source – FW 1.2 (or higher)

Guardian 19052 & 19053 / 1010, 1030 & 1030S Hipot Testers

- Firmware 4.30 (or higher)

- RS232 installed (G36)

Guardian 19056, 19057 and 19057-20 Hipot Analyzers Chroma 16502 and QuadTech LR2000 Milliohmmeters

- A165014 Temperature compensation card supported

Additional Instruments Supported: Guardian 19572 / 1050 Ground Bond Tester

- Firmware 1.00 (or higher)

- RS232 installed (G36)

Hybrid 19035 / 2000 AC/DC/IR/DCR Safety Analyzer

- Firmware 1.14 (or higher)

19200 / Matrix 8000 Scanning System

- AC Line Module / 9 19200099

- GBF-2 Module / 9 19200799

- Earth Module / 9 19200499

- AC Line 2 Module / 9 19200

- General Module / 9 19200399

- Switch Module / 9 19200899

Guardian 6000 (Obsolete)

- Firmware 1.08 (or higher)

- RS232 installed (G26)

- Scanners: (3 Total)

- 1 INT Scanner: 6000-01/A190302, -02/A190303 or -03/A190304 (Optional)

- 2 EXT Scanners: 5000-01, -02, -03 or -04 (Optional)

Guardian 6100 (Obsolete)

- Firmware 1.08 (or higher)

- RS232 installed (G26)

- Scanners: (3 Total)

- 1 INT Scanner: 6000-05/A190306 (Standard)

- 2 EXT Scanners: 5000-01, -02, -03 or -04 (Optional)

Guardian 6200 (Obsolete)

- Firmware 1.08 (or higher)

- RS232 installed (G26)

- Scanners: (3Total)

- 1 INT Scanner: 6000-04/A190306 (Standard)

- 2 EXT Scanners: 5000-01, -02, -03 or -04 (Optional)