Capacity testing is a crucial component of testing a battery’s charging and discharging capabilities. Conventional charge/discharge testers can only perform tests using constant current charging (CC) or constant current-constant voltage (CC-CV) methods. However, in real-world battery usage, the Battery Management System (BMS) dynamically adjusts the output based on factors such as temperature and safety conditions. To ensure accurate battery testing that corresponds with real-life scenarios, dynamically modifying the test conditions based on incoming BMS data has become essential.

Chroma’s proprietary BatteryPro software provides a solution to this challenge. BatteryPro continuously receives and processes the BMS data used to monitor battery temperature and voltage. It also utilizes BMS signals with a user-defined unique identifier (ID) to receive BMS data under constant current (CC), constant current-constant voltage (CC-CV), constant power (CP), or constant voltage (CV) mode. The software then uses this data to dynamically adjust output current, voltage, and power, ensuring that the battery does not carry excessive voltage or accumulate too much heat while also providing accurate capacity measurements.

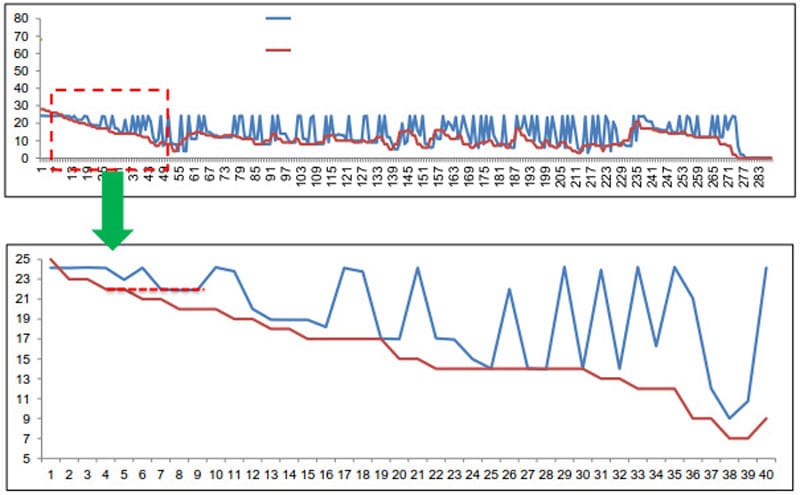

Using BMS data to adjust the current during battery testing offers several practical benefits. It improves the accuracy of capacity measurements and allows battery designers to simulate long-term usage scenarios by designing duty cycles and then running multiple cycles (as shown below), which helps to determine battery lifespan and make appropriate adjustments to the design of the battery or BMS.

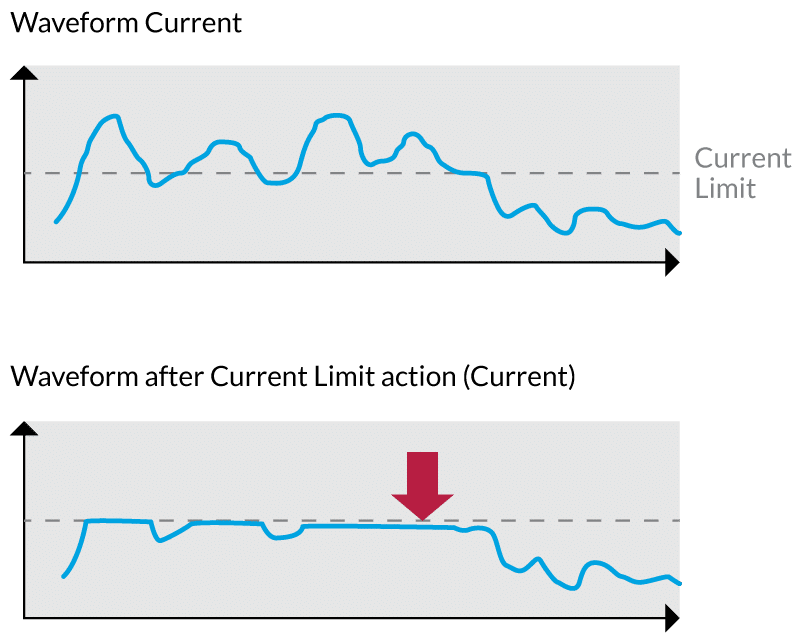

Alternatively, users can utilize BatteryPro’s Waveform Mode to convert duty cycles into waveform files. By setting the BMS data to output maximum current, users can simulate the behavior of an Engine Control Unit (ECU) that limits throttle response based on battery temperature. Even if the driver presses the pedal all the way down, the ECU will restrict the battery’s discharge capability. Once the battery temperature decreases to an acceptable level, the original charge/discharge cycle is resumed. This feature significantly enhances the realism and flexibility of the testing scenario.

To sum up, using Chroma BatteryPro to dynamically adjust the test current offers an array of advantages for EV battery testing. It enhances testing efficiency and accuracy, improves testing safety, reduces battery damage and failure rates, and supports a wide range of battery types.