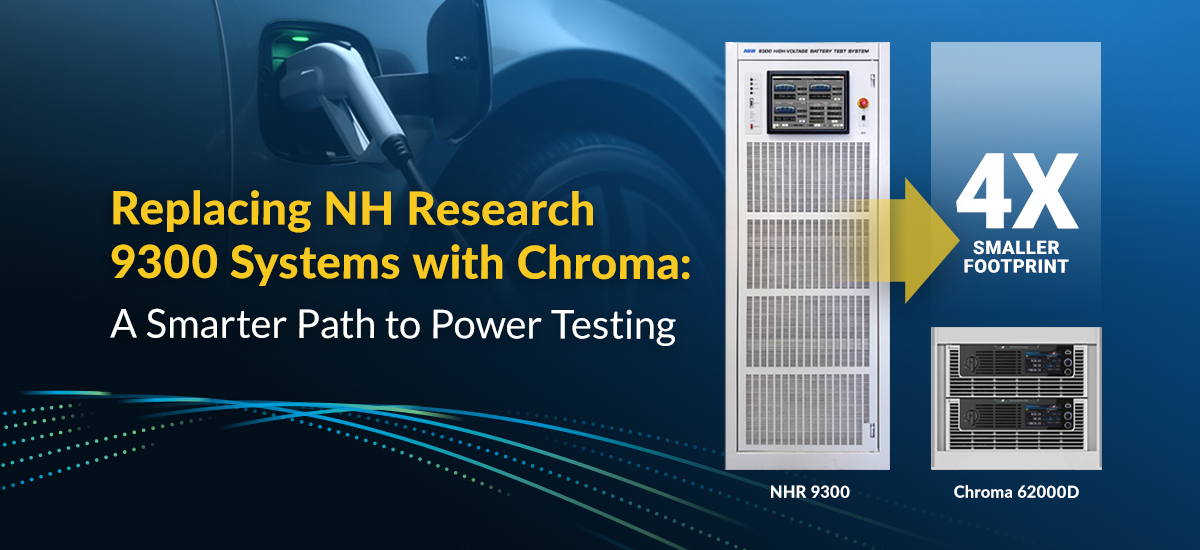

With the discontinuation of NH Research (NHR) 9300 systems, many labs are seeking replacements that deliver higher flexibility, performance, and modern integration. Chroma’s 62000D regenerative DC power systems offer a clear upgrade—combining compact modular design, advanced control, and industry certifications that ensure long-term dependability.

***NI’s retirement of NHR products means you should budget for migration before 12/31/2026.

Direct Comparison: Chroma 62000D vs. NHR 9300

| Specification |  Chroma 62000D Chroma 62000D |

NHR 9300 NHR 9300 |

|---|---|---|

| Power Rating | 90 kW (2×62450D-2000HL) | 100 kW |

| Voltage / Current Range | High (2000V / 60A / 45kW)

Low (650V / 180A / 45kW) Two voltage & current ranges |

1200 V / 167 A |

| System Architecture | Modular 2-unit system

Modularity provides higher uptime and faster support as any failure only partially reduces system capacity. One spare module takes only 4U of space and costs less than a 1/6th of system cost. Modular design allows the system to scale up in 45kW increments. The 45kW units can support up to 40 units in parallel. |

Single-unit system

Any failure takes down the whole system. A spare system doubles the cost and space. A fixed, single-box system cannot be re-purposed at multiple locations. The whole 100kW can be dedicated to only one application, regardless of its lower power requirements. |

| Rack Height | 8U (13.8″) – standard 19″ rack | 78″ – non-standard cabinet |

| Weight | 318 lbs | 1200 lbs |

| Response Time | <1.5 ms (6× faster) | <10 ms |

| HIL Integration | Analog + Optical (HIL ready) | None |

| Certifications | ISO 9001 & ISO 17025 | No, not certified |

| Modularity Benefits | Allows for flexible use of 6kW, 12kW, 18kW, 36,kW, and 45kW modules | None |

| Power Efficiency | 215% higher current per module | Lower current density |

(Based on Chroma and NHR published data)

Smaller, Faster, and More Efficient

Chroma’s modular design provides a footprint that is 4 times smaller and one-fourth the weight of an equivalent NHR 9300 system. Each Chroma module operates independently, allowing partial capacity use even if one unit requires service. This ensures higher uptime, lower maintenance costs, and greater ROI.

The system’s fast transient response (<1.5 ms) makes it ideal for dynamic applications such as hardware-in-the-loop (HIL) and EV drivetrain testing, where precise real-time control is essential. Additionally, optical HIL inputs enable low-latency interfacing with digital controllers—something unavailable on the NHR 9300.

Enhanced Accuracy and Control

Chroma’s dual-range voltage and current configuration provides high-accuracy performance across both low- and high-power applications. The digital control architecture allows faster command response, better measurement resolution, and smoother transitions during source/sink mode switching.

These systems integrate seamlessly with PowerPro 5 software, enabling easy automation, waveform editing, and data logging. For custom integration, Chroma supports LabVIEW, Python, and C# interfaces for direct scripting and control.

Certified and Supported Globally

Chroma systems are ISO 9001 and ISO 17025 certified, ensuring manufacturing quality and calibration traceability that meet international standards. Combined with Chroma’s global service network, users gain reliable long-term support—a critical advantage as NHR products reach end-of-life.

Conclusion: Future-Ready Testing

Transitioning from the NHR 9300 to a Chroma 62000D solution isn’t just a replacement—it’s a technological leap forward.

With a modular design, faster response time, certified accuracy, and enhanced HIL readiness, Chroma delivers the performance and flexibility required for modern power testing environments.