Ripple most commonly refers to an undesirable amount of AC voltage fluctuation on the DC power supply. During vehicle charging and power conversion, EV batteries constantly have to face such troublesome power ripples. In the long run, this may accelerate battery degradation, especially in harsh low-temperature environments. EV batteries thus require ripple current testing to ensure quality.

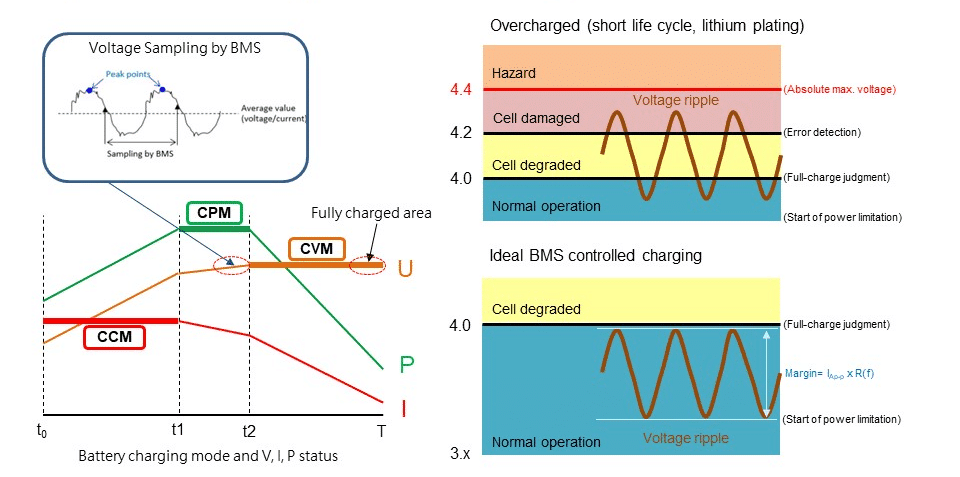

When the power is converted, it is induced from devices such as the motor driver, on-board charger, and DC charge station, as well as brake charging, which are the main sources of ripple current. When the battery either is fully charged or has low capacity, transient overcharge or overdischarge may occur. Present BMS protection mechanisms ranged between 10mS and 1mS cannot achieve voltage protection through timely external blocking of transient overcharge and overdischarge at frequencies above 100Hz-1kHz.

Each transient overcharge and overdischarge may only be a slight deterioration, but accumulation over time will cause capacity degradation. As a result, the lifespan of the battery in the vehicle turns out to be shorter than the guaranteed mileage! Many studies have shown that battery overcharge could trigger the deposition of lithium metal on the surface of the negative electrode. Part of the lithium metal will become dead lithium and can no longer participate in the redox process, causing the capacity to degrade. Serious deposition of lithium dendrites could even generate an internal short circuit in the battery. On the other hand, overcharge of the battery cell may affect the SEI layer to decompose. In the next charge, this regenerates the SEI layer and consumes lithium ions, which will cause lithium loss. It may also induce the emanation of cathode copper, and deposition of metal burrs on the positive electrode increases the risk of a short circuit.

▲ Figure: Impact of Current Ripple on Li-Ion Batteries

Ripple current testing assesses battery endurance to transient and excessive use

Chroma’s ripple current test solution can increase the tolerance of the battery in transient use exceeding its specifications and, through sine wave, can simulate the power supply ripple of vehicle charging. If you want to shorten the test time, the most common methods are enhancing the ripple current amplitude or testing in a low temperature environment. Chroma’s test solution offers the following characteristics:

• 100Hz~20kHz with up to 150Ap-p amplitude for ripple impact analysis on a diversity of EV batteries

• Independent AC/DC circuits for the lowest impact on DC charge and discharge cut-off judgement

• Ripple current superposition on various CC, CV, CP charge/discharge modes

• Programmable integrated chamber control

Major European battery manufacturers have recently successfully adopted Chroma’s current charging/discharging test solution. For more relevant information on Chroma products, please visit our website and share your testing needs through an inquiry. We are happy to be of your service.

![[Tech Review] Why Do EV Batteries Need Ripple Current Testing?](https://www.chromausa.com/wp-content/uploads/2021/03/03082021_NL.jpg)